Why is a centrifugal oil separator so important in today’s modern high performance diesel engines?

The Problem

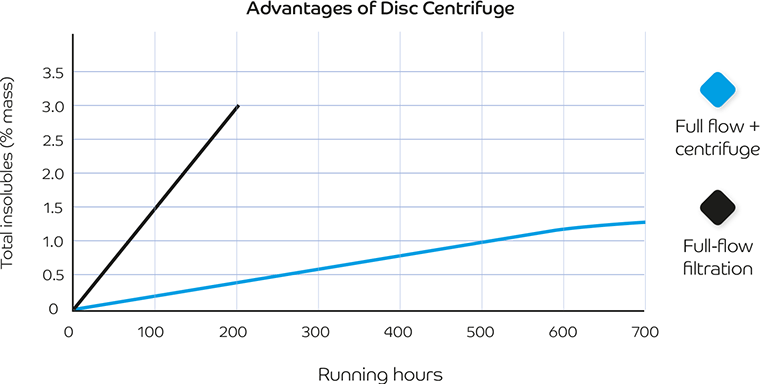

Nearly all full-flow oil filters are designed to clean the lubricating oil which lubricates the moving parts of engines. They are designed for a certain flow rate and pressure drop. However, to get the necessary flow rates and pressure drops required there is a trade-off in performance. Smaller submicron particles pass through the filter media continually.

These particles build up in the lubricating oil, causing unnecessary wear and damage to the engine, which in turn leads to lower engine performance and increased engine emissions.

They also shorten the life of the lubricating oil as the level of contaminants increases.

With today’s emission controls getting tighter and tighter, it is increasingly important to remove these contaminants before they cause any damage to both the engine and the lubricating oil.

The Solution

By adding an MP centrifugal oil separator the amount of particles in the lubricant is significantly reduced. The centrifuge bypasses only 10% of the dirty oil but by doing so it significantly improves the quality of the lubricant increasing the life and efficiency of the full-flow filter.

With fewer particles moving around the engine, wear and tear of components is greatly reduced and has the added bonus of reducing man-hours due to unnecessary servicing. Environmentally, fewer contaminants in the oil also mean lower emissions - a must in today's environmentally sensitive times.

Only 10% of dirty oil is fed through the MP centrifugal oil separator, however, this provides significant improvements to running times between services and lubricant longevity. It also reduces man-hours by eliminating unnecessary servicing.

The MP centrifugal oil separator is impressively effective.

Contact the IOW Group

We will get back to you as soon as possible

Please try again later