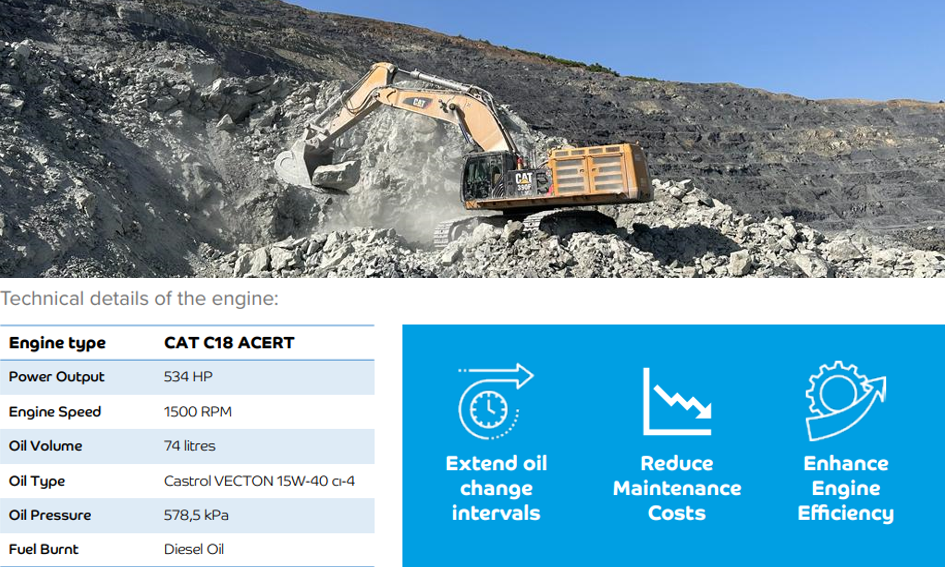

Overview

A customer who operates heavy construction equipment expressed an interest in exploring options to enhance maintenance and longevity of their CAT390F Excavator's C18 ACERT Engine. Contaminants in engine oil, such as dirt, metal particles, and other impurities, can have adverse effects on engine performance and engine lifespan. To address concerns, the customer sought to test the IOW MP090 Centrifugal Filter to mitigate these issues and monitor their lubrication oil properties.

Installation

During the preliminary site visit, a thorough assessment was conducted to ascertain the optimal position for an IOW MP090 to be installed. The goal was to ensure a seamless integration of the IOW Group Centrifugal Oil Filter onto the CAT 390F Excavator's engine with the feed circuit for the filtration system tapping into the engine's oil line. This ensures a smooth and consistent flow of oil into the centrifuge for effective filtration.

As a standard feature of IOW Group Centrifuges, our remote monitoring capability was seamlessly integrated via a Bluetooth control panel mounted within the cabin. This is so operators can easily monitor the performance of the centrifuge whilst the engine is in use, ensuring it's running optimally and to be notified when a service/clean is required.

Results

Following an initial 700-hour run time, the IOW MP090 underwent servicing, where several observations were made:

- Average RPM: 5800

- Sludge Cake Thickness: 11mm

- Total Wight of Contaminants: 475g

This trial was conducted with newly replaced engine oil, showing how efficient the MP090 is at removing harmful particulates which would have otherwise circulated throughout the engine.

Through oil analysis, we were able to gain insight into the engine's condition. Results indicated that the crankshaft oil experienced oxidation, likely due to on-site operation and harsh environmental conditions. However, by installing an IOW Group Centrifugal Filter, the customer benefitted from:

- Sustained Lubricant Properties: the centrifuge consistently maintained the oil lubricant properties, mitigating the damaging effects of oxidation and soot accumulation.

- Contaminant Removal: it efficiently removed waste products formed within the engine, safeguarding the engine's overall performance and longevity.

- Metal Particle Removal: the centrifuge provided effective at removing metal particles suspended within the oil, further enhancing engine protection.

Conclusions

The IOW MP090 consistently maintained the optimal properties of the engine's lubrication oil, thereby extending the operational life of the oil as well as extending the engine's lifespan.

As a result of these benefits, the customer can achieve significant cost savings:

- Extended Oil Change Intervals

- Reduced Maintenance Costs

- Enhanced Engine Efficiency

The installation of the MP090 not only ensures financial efficiency, but also contributes to the engine's reliable and efficient operation, meeting the customer's objectives in a cost-effective and sustainable way.

Looking to upgrade your filtration system? Contact us or visit Centrifugal Oil Filter page for more information.

Contact the IOW Group

We will get back to you as soon as possible

Please try again later