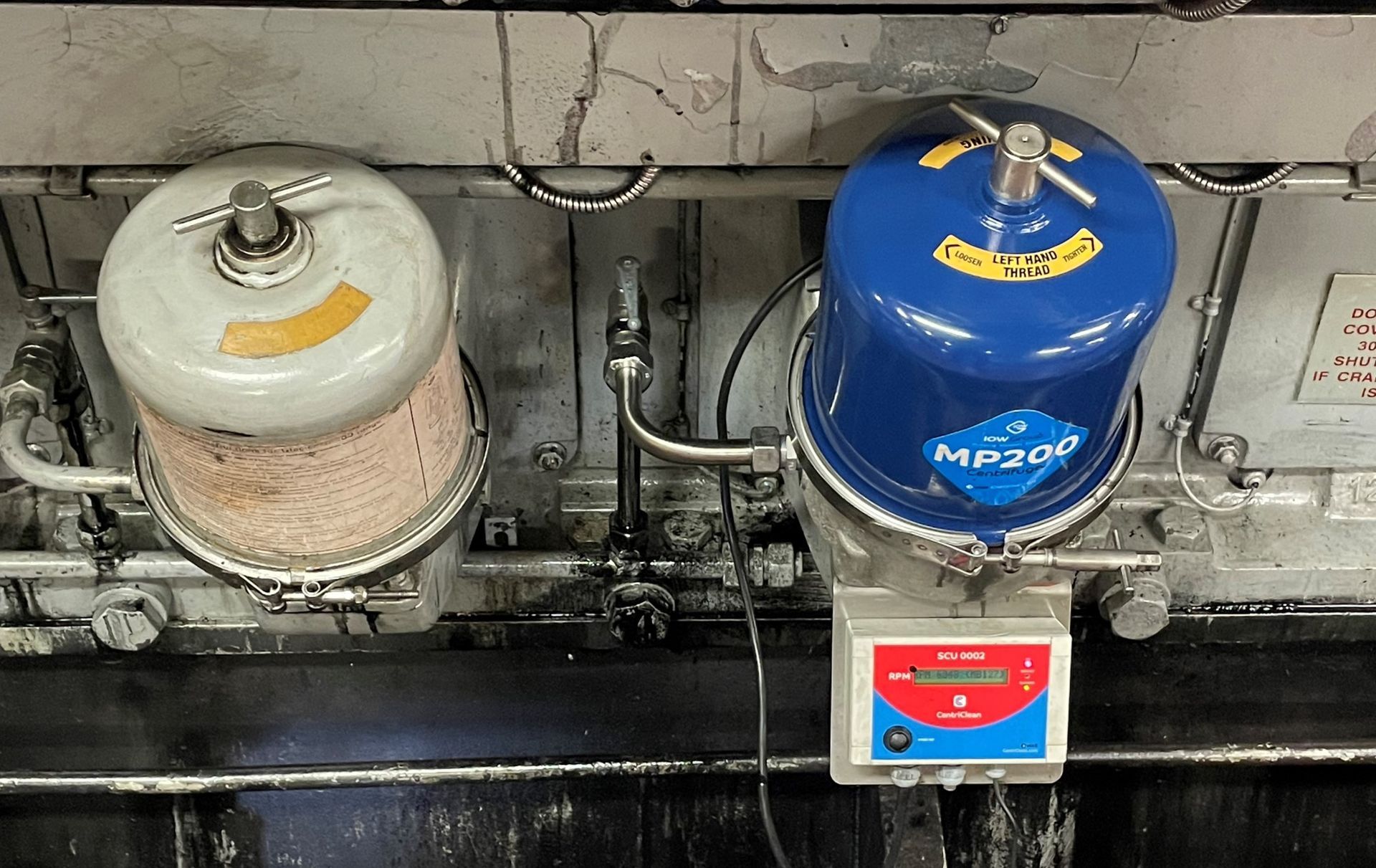

A customer wanted to enhance contamination and soot removal from their Wartsila Nohab WN25 16V25 marine diesel engine where they had previously relied on two (2) Glacier GF200-12 centrifugal oil filters. To assess a more effective solution, the customer chose to replace one of the Glacier GF200 centrifugal filters with an IOW MP200 centrifuge filter.

This approach allowed for direct side-by-side comparison of the Glacier GF200 and IOW MP200 centrifuges, where both utilized the same engine oil pump, piping, and operational run time. Following a 46-hour test run, both centrifuges were taken offline, inspected and cleaned.

Comparing Performance: Glacier GF200 vs. IOW MP200

After a 46-hour run time, the results spoke volumes:

- Glacier GF200 Centrifuge: The Glacier GF200 collected approximately 6mm (1/4") of sludge cake. The centrifuge lacked remote monitoring capabilities, making it impossible to report on the centrifuge's RPM during operation.

- IOW MP200 Centrifuge: In contrast, the IOW MP200 centrifuge displayed remarkable performance, accumulating more than 19mm (3/4") of sludge cake. What sets the IOW Centrifuge apart is our remote monitoring as standard (provided by our CentriClean SCU0002 remote monitor), which during operation, displayed an RPM of 6,048.

IOW Group's Revolutionary Centrifugal Oil Filters

The test results clearly demonstrate the exceptional advantages of IOW Group's centrifugal oil filters. By simply replacing the Glacier GF200 centrifuge with an IOW MP200 centrifuge filter, the contaminant removal rate surged 216.6%. This significant improvement in separation efficiency is a testament to IOW Group's commitment to delivering optimal results and reducing life-cycle costs.

When it comes to centrifugal oil filters, IOW Group stands at the forefront of innovation, and the Wartsila side-by-side engine test solidifies the IOW Group MP200's superior performance over the Glacier GF200 centrifuge.

When you demand the best, choose IOW Group.

To upgrade your filtration system, contact us today. Or for more information, visit our Centrifugal Oil Filter page.

Contact the IOW Group

We will get back to you as soon as possible

Please try again later