Our Process

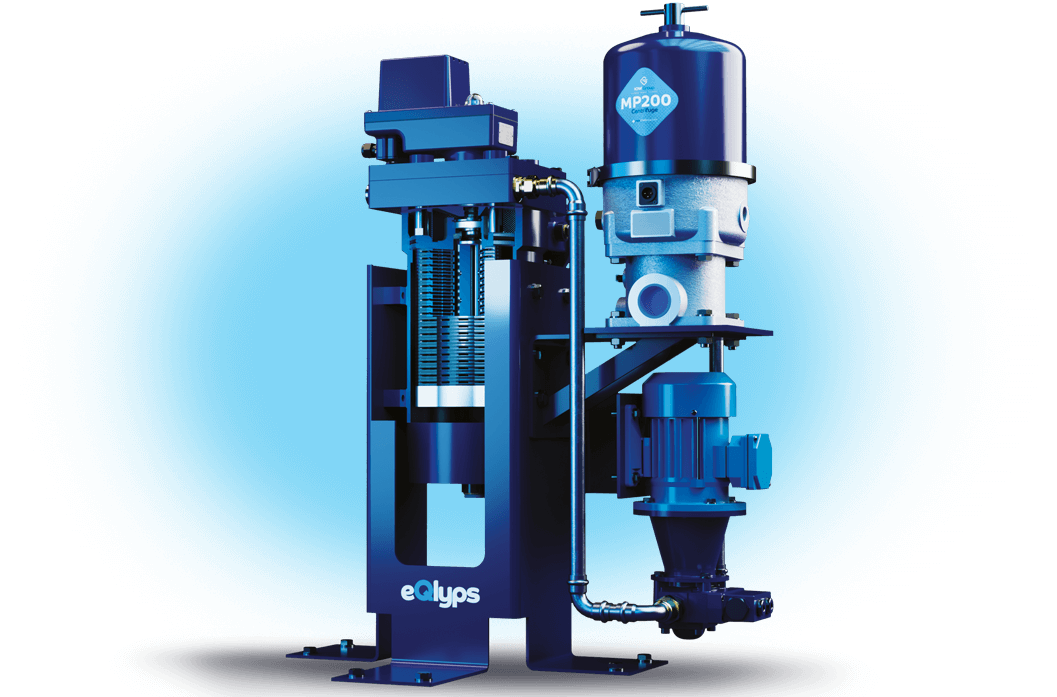

At the IOW Group, we strive to go one step further. With advanced features offered by no other manufacturer, including remote monitoring and bowl disc separators, our specialist technology puts us at the forefront of the oil filtration industry.

All of our equipment is manufactured and assembled in our UK facility, located on the Isle Of Wight. We are ISO certified and closely follow both British and International engineering standards, ensuring a consistently high standard of quality throughout our product range. Wondering how we work our magic?

Read on to discover our time-tested design and manufacturing process.

1. Research and Development

It all starts with an idea. Our dedicated research and development department begin by looking at all potential avenues for improvement, whether in efficiency, consumption, or versatility. They analyze current product performance and research ways to optimize it further, taking into account the demands of each industry.

2. Design

Once the initial research has been carried out, we move onto the design stage.

We use advanced digital modelling technology to plan out our designs, experimenting with various components and configurations. This gives us an accurate look at how the design will perform in reality, and allows us to tweak even the smallest details for maximum performance.

We don’t finalize designs until we are completely satisfied they meet the same innovative standards we are known for worldwide.

If your project is more specialized, we can also design a filtration solution uniquely suited to your environment. To discuss your design requirements,

book a consultation today.

3. Manufacture and Assembly

With the design finalized, we can finally begin the manufacturing process.

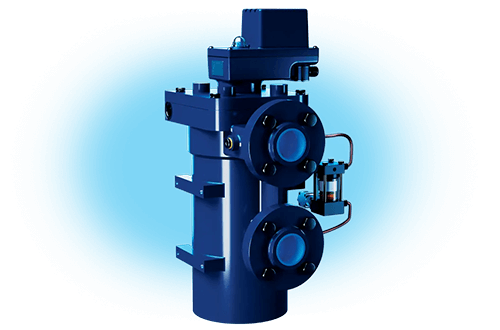

Our machinists use state-of-the-art equipment from Kawasaki Robotics to create each component, including our rotors, casings, and shafts. They then assemble our products to the strictest specification. Products we manufacture include:

- Centrifugal oil separators

- Positive displacement triple screw pumps

- Separator control units

- Pressurized drain systems

- eQlyps, our complete filtration solution

All of our standard products are designed to fit a variety of existing flanges and footprints for easy installation.

4. Quality Control

We pride ourselves on the outstanding quality of our products, which is why we never send out a piece of equipment without testing it extensively first.

We use our dedicated test rig to check for quality and reliability in all applications, whether marine, transport, military, or any other sector. This ensures the product you receive will perform perfectly in any condition.

5. Stockholding

Our UK manufacturing facility and international warehouses are kept fully stocked at all times, so we can send out your new components without delay.

6. Delivery

We deliver our products to customers worldwide. We take steps to prevent damage in transit and strive to have your order arrive at your door in the shortest time possible, no matter where you are in the world.

7. Ongoing Support

We’re passionate about getting you the results you expect. Before you make a purchase, we’re happy to discuss your current engine set up and advise you on the best option to suit it.

After you start using your new product, we’re on hand to offer support on getting the most out of your engine, as well as recommend ways to further optimize efficiency and reduce your carbon footprint.

We offer an 18-month warranty on delivery (excluding consumables) or a 12-month warranty on installation. In the unlikely event a fault occurs, you’ll have peace of mind that your new device is fully covered.

Book a Consultation

Innovation is our business. Our oil filtration solutions are the most advanced on the market, offering unparalleled levels of efficiency and performance. For an engine that works faster, cleaner, and better, the choice is clear.

Book a consultation online.

To find out more, get in touch with one of our experts today.