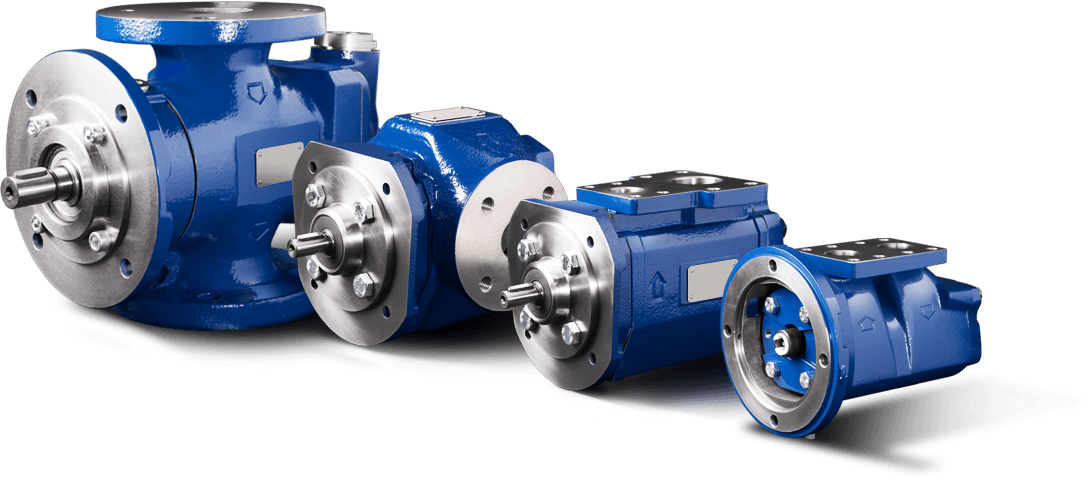

Mechline is a mechanically sealed pump

designed to optimize performance and efficiency.

The mechanically sealed pumps are financially more economical due to the shaft seal design.

The main difference between the mechanically sealed pump is its designation of high or low temperature, with the pump designed to be coupled directly to an electric motor of flange type and with options of a pressure relief valve.

Mechline 025 N2/L2

Flow volume of

11 - 42 l/min

(3 - 11 gpm)

Mechline 032 N2/L2

Flow volume of

21.6 - 95.2 l/min

(5.7 - 25.1 gpm)

Mechline 038 K2/N2/D2

Flow volume of

46 - 179.8 l/min

(12.2 - 47.5 gpm)

Mechline 125 N3/L3

Flow volume of

11 - 42.5 l/min

(2.9 - 11.2 gpm)

Mechline 225 N2/L2

Flow volume of

11 - 42 l/min

(3 - 11 gpm)

Mechline 232 N2/L2

Flow volume of

21.6 - 95.2 l/min

(5.7 - 25.1 gpm)

Mechline 238 K2/N2/D2

Flow volume of

46 - 179.8 l/min

(12.2 - 47.5 gpm)

Mechline 345 N2/K2

Flow volume of

80 - 268 l/min

(21 - 71 gpm)

Mechline 352 N2/K2

Flow volume of

125 - 418 l/min

(33 - 110 gpm)

Mechline 025 N2/L2

Flow volume of 11 - 42 l/min

(3 - 11 gpm)

Mechline 032 N2/L2

Flow volume of 21.6 - 95.2 l/min

(5.7 - 25.1 gpm)

Mechline 038 K2/N2/D2

Flow volume of 46 - 179.8 l/min

(12.2 - 47.5 gpm)

Mechline 125 N3/L3

Flow volume of 11 - 42.5 l/min

(2.9 - 11.2 gpm)

Mechline 345 N2/K2

Flow volume of 80 - 268 l/min

(21 - 71 gpm)

Mechline 352 N2/K2

Flow volume of 125 - 418 l/min

(33 - 110 gpm)

The IOW Group answers some regularly asked

questions about our Mechline pumps

- Able to handle fluctuating flow rate and pressure without losing efficiency

- Screw pumps are smoother, lower vibration pumping

- Better suction capabilities

- Smaller footprint perfect for limited spaces

- Better mechanical efficiency

- Able to operate at higher motor speeds

A Mechline pump is a triple screw pump with a mechanical seal inside. A mechanical seal is a simple method of containing lubricating fluid within the triple screw pump. A mechanical seal maintains the pressure of the lubricating liquid being pumped, using sealing gaskets and O-rings to complete the seal, and withstand any friction caused by the rotor turning.

In Mechline mechanically sealed pumps, a micro-gap is created within the seal to allow a leak path. The seal faces cannot be permitted to run dry as the frictional heat build-up will very quickly cause severe seal face damage and extensive leakage. All mechanical seals must leak to operate properly. This makes it impossible for a mechanical seal to be leak-free. The amount and visibility of the leakage will vary from pump to pump.

Mechline (mechanically sealed) triple screw pumps are typically lower-cost seals. They are an effective choice for creating a seal within the triple screw pump. By fitting a mechanical seal to your triple screw pump that is the optimum design size and material, you can extend the lifespan and productivity of your machinery/applications.

Magnaline and Mechline pump both have their advantages; it depends upon the environment and customer requirements. Our team can advise which pump type best suits your needs and can quote you both the Mechline and Magnaline alternatives. If you need further information and want to discuss which pump type is best for you, contact one of our team here.

Contact the IOW Group

We will get back to you as soon as possible

Please try again later