Overview: MAN B&W 6L28/32HP on a RORO Vehicle Carrier

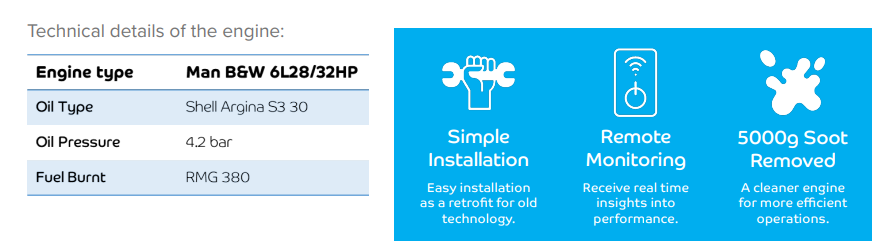

A client undertook a trial period with our IOW MP400 Centrifuge, which was installed as a retrofit on a MAN B&W 6L28/32HP engine. The objective was to assess the performance differences and determine whether IOW Group's separation capabilities could enhance engine reliability and performance. Prior to the installation of IOW Group's MP400, the engine had been in operation for over 67,000 hours, rendering it highly susceptible to wear and degradation. Consequently, it becomes imperative to remove as much harmful particulates as possible to prolong engine life, as well as extend primary filter life to minimize maintenance requirements.

Installation on a MAN B&W 6L28/32HP Engine

Upgrading the oil filtration system with an IOW MP400 centrifuge is easy and straightforward. They have a bolt-on, bolt-off design to make transitioning to an efficient centrifuge a smooth process. With our CentriClean SCU0002, the client is able to monitor the performance of their MP400 remotely, which other manufacturers are unable to offer. This also provides the scope for engineers to ensure the centrifuge is running as expected and are notified when a service is required to keep operations running smoothly.

Results

After an initial runtime of 111 hours, the IOW Centrifuge removed a staggering 5,000g of sludge from the engine's lubrication oil, 26mm thick. This is a sludge removal rate of 45g per hour, significantly more than standalone filters.

The centrifuge was then serviced again at 172 hours. this time removing an impressive 4,500g of soot from the oil. With remoting monitoring, engineers were able to record a RPM 3,816 confirming the centrifuge is running as intended and at optimal efficiency.

Conclusion

In conclusion, the IOW Group Centrifugal Filters provide superior performance, with the MP400 effectively removing 5,000g of sludge from lubrication oil within 111 hours. This results in a cleaner engine, dramatically enhancing operation and efficiency whilst reducing fuel consumption and lowering maintenance costs. Additionally, the reduced sludge accumulation positively impacts the lifespan of the engine and primary filters, further contributing to a substantial return on investment (ROI) for the customer in the long run.

Impressed with these results, the customer has decided to roll out our technology across more vessels within their fleet.