Overview

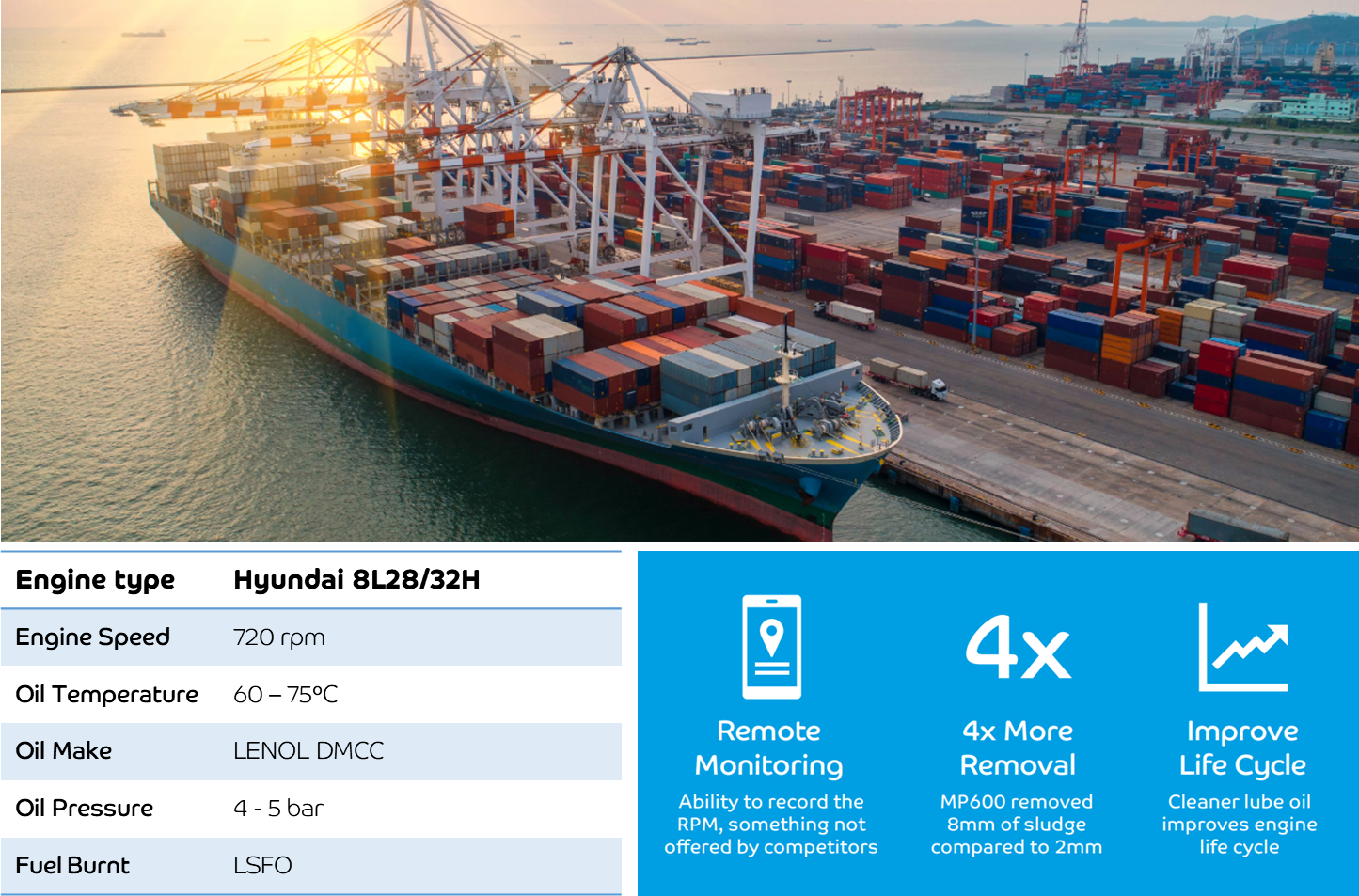

A customer based in Dubai wanted to evaluate the performance of an IOW Group Centrifuge compared to an existing, old technology FM600. Contaminants present in lubrication oil, including dirt, soot and metal particles can significantly hinder engine performance, making it susceptible to degradation and wear on crucial components. In the marine sector, continuous operation is vital, and so a vessel's engine is a valuable asset which must be maintained for optimal reliability.

Installation

The existing on-engine centrifuge was replaced with a new IOW MP600 Centrifuge on Auxiliary Engine No.1, at the same time keeping the existing old technology centrifuge on Auxiliary Engine No.4 as a comparison. At a pressure of 4.6 bar, the MP600 recorded speeds of 4062rpm on the remote monitoring device at a runtime of 200 hours. In this comparison, it's important to note that both Auxiliary Engines No.1 and No.4 had identical oil conditions.

Results

For a direct and fair comparison of the old FM600 and new IOW MP600, both centrifugal filters were dismantled and inspected after a runtime of 200 hours. The results are as follows:

Conclusion

The IOW Group MP600 Centrifugal Filter has demonstrated remarkable superiority over the outdated FM600 centrifuge, delivering 4x better separation of harmful particulates within the same time frame and engine conditions. This direct comparison highlights the undeniable advantages of upgrading to new technology, ultimately enhancing both engine reliability and performance. By simply retrofitting a new IOW MP600, the customer can expect a rapid return on investment through extended lube oil changes and reduced maintenance expenses.

"No.1 Aux Engine with the new type of centrifuge has extreme performance and separation in comparison to the No.4 Aux Engine with old type centrifuge.. as the new type centrifuge has been separating 3.4g more sludge per hour."

Contact the IOW Group

We will get back to you as soon as possible

Please try again later