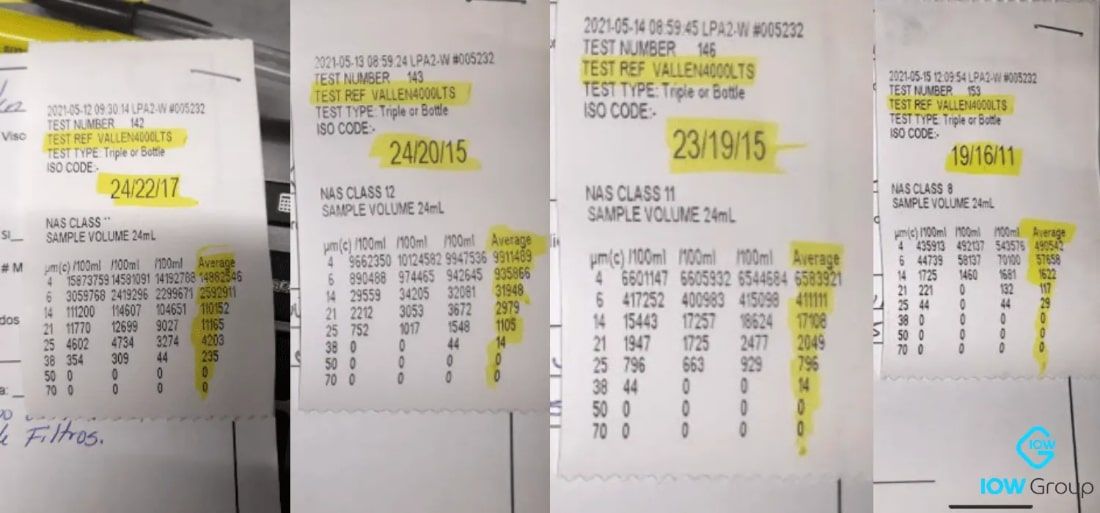

When an IOW MP600 centrifuge filter was installed at a hydraulic reclamation site oil samples were taken at regular intervals over 5 days. They quickly showed the excellent performance of the centrifuge on the oil cleanliness levels.

Hydraulic oil may appear clean, bright, and transparent, however, appearances can be deceiving! The human eye cannot detect fine contaminants smaller than 50 μm. The particles are measured in μm, which is a millionth of a meter, and it is exactly these small particles that can severely disrupt a hydraulic system. Especially particles with a size of 4 μm can cause serious problems for machinery.

The requirements placed on these fluids are constantly increasing as they must keep up with technological advances and hydraulic system development, which as they become more and more powerful they also become more compact. Smaller oil gaps mean these small particulate do increasingly more damage to your system. Effective filtration solutions are essential in controlling particle contamination.

Without filtration, these particulates cause most hydraulic malfunctions. The effects can often be severe. Particles cause wear in pumps, valves, motors, gaskets, and hoses as well as major engine components. Primary filters clog up quicker and must be exchanged and valves can become blocked. Leaks occur and the effectiveness of the hydraulics system is decreased.

The contamination levels are calculated by the size and quantity of particles found in the oil. Oil samples must be taken at regular intervals to establish the effectiveness of filtration systems in place. The samples are tested, and data outlining particle size and quantity are taken to formulate an ISO code indicating cleanliness levels in the oil.

How did installing an IOW MP600 improved the ISO Code?

Our customer was struggling to cost-effectively reach the ISO code in the range of 17/15/12 or 16/14/11 with their current processes. They were using a vacuum dehydration system in combination with magnetic filter elements. Opting to install the IOW MP600 centrifuge filter and CentriClean SCU0002 remote monitoring unit they were quickly satisfied with their choice when the ISO cleanliness codes rapidly improved to reach their target!

The IOW centrifuge filter utilizes a variety of innovative filtration features to achieve the highest levels of separation. The IOW centrifuge filter has a central disc stack that helps draw out even the smallest particulate. The increased surface area created by the bowl discs aids superior separation and assists in pushing the particulate to the bowl wall. The IOW centrifuge filter spins faster than any other centrifugal filter available meaning centrifugal force is stronger also assisting in the finer filtration. Combined with remote monitoring to ensure your IOW centrifuge is running optimally all work together to achieve the cleanliness targets you require.

Regular oil analysis will help establish how effective your centrifuge filter is as indicated in the results above

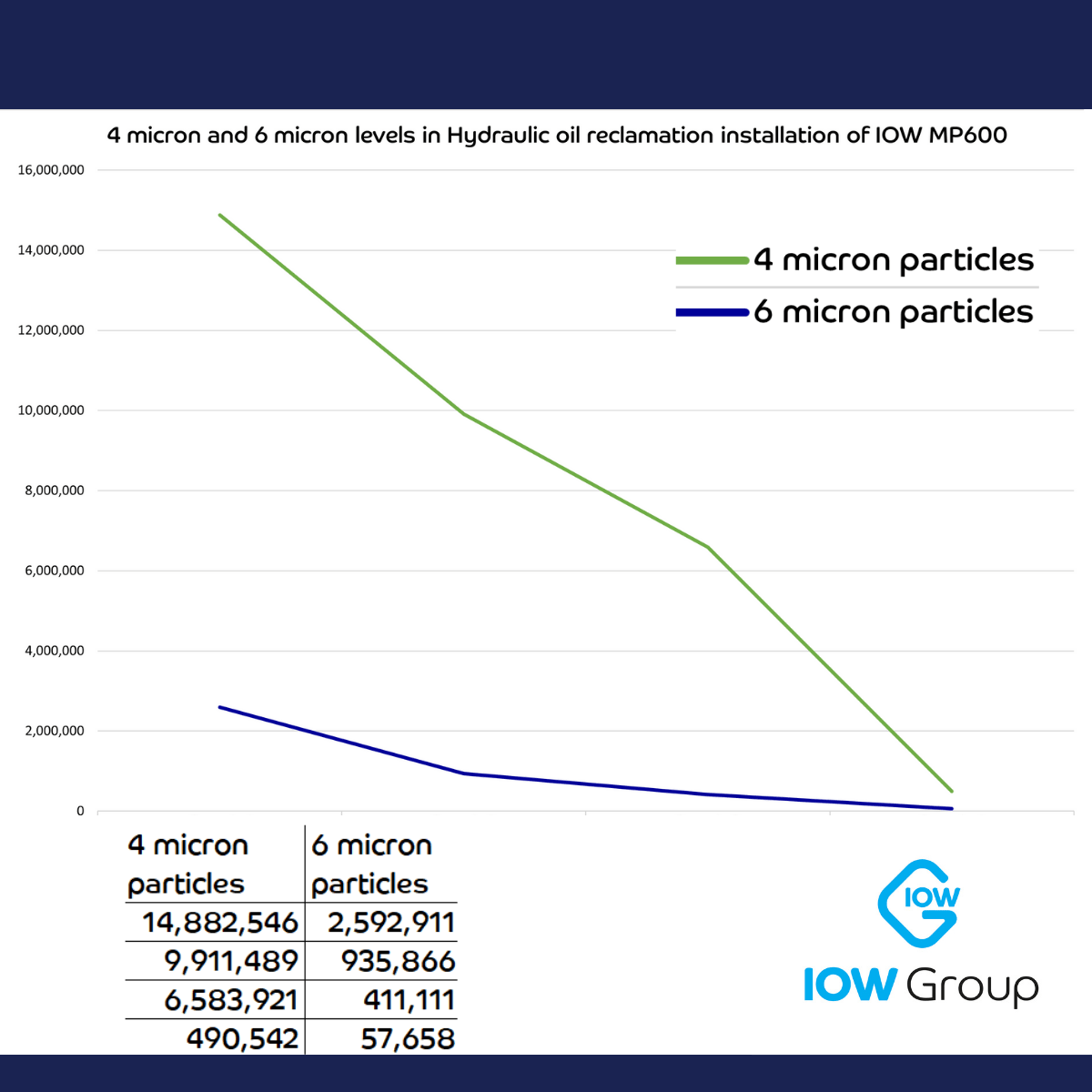

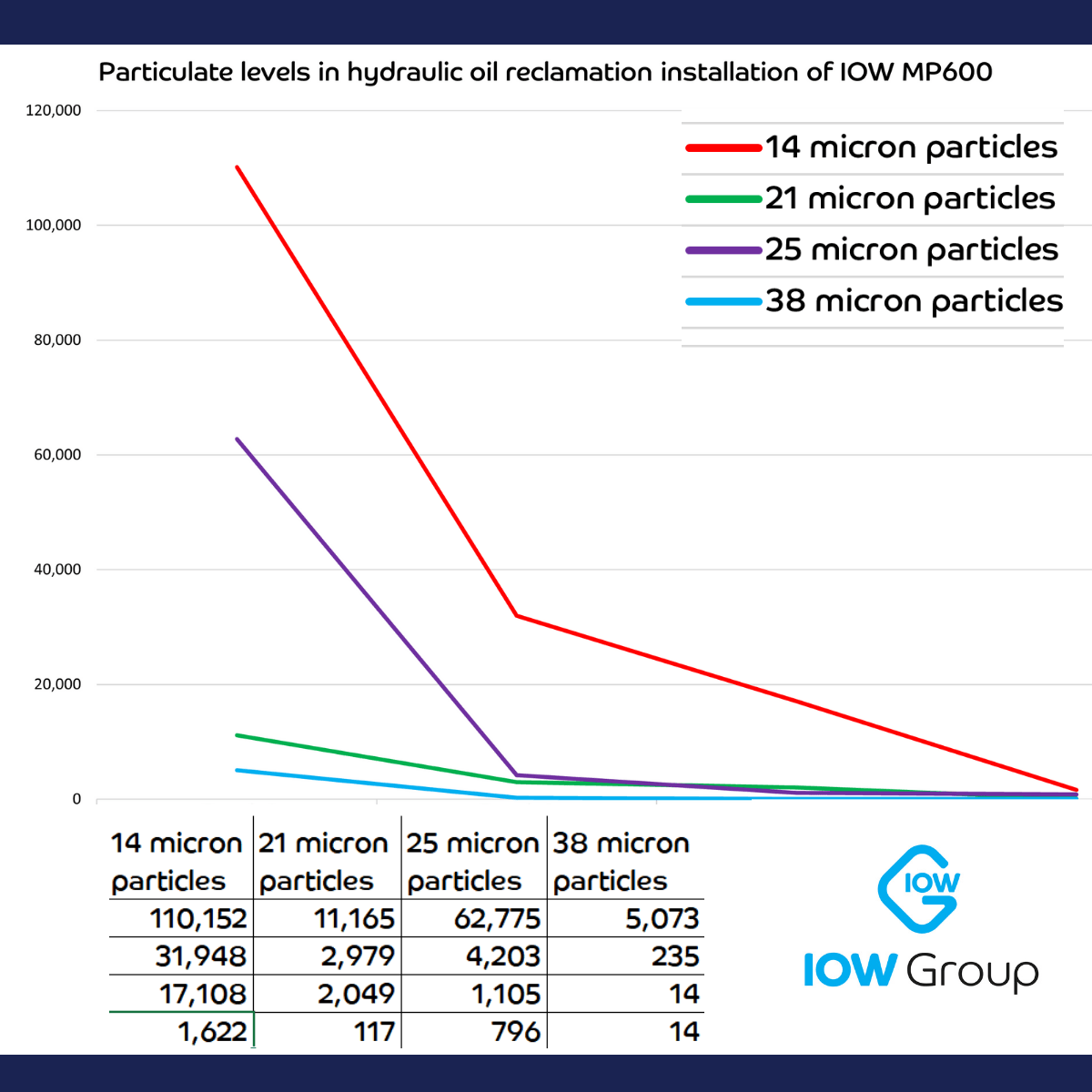

The graphs below illustrate the rapid decline in particles in the hydraulic oil. Any particles bigger than 25 μm were reduced down to zero. Thanks to the impressive performance of the IOW centrifugal filter all contaminants showed a huge decrease once the IOW centrifuge was installed.

The graph above highlights the exceptional performance of the IOW centrifuge filter in removing 4micron and 6micron sized particulate from hydraulic oil

4 micron and 6 micron particles have the ability to cause serious problems within your hydraulic system and often cause the most damage. As per the data above from our recent installation, using an IOW centrifuge filter can hugely impact the number of these particulate found in the oil. The removal of these contaminants protects systems from unnecessary wear and can have a big impact on extending the lifespan of machinery, therefore lowering the total cost of ownership (TCO).

The graph shows the effectiveness of the IOW centrifuge filter on particulate sized 14 microns and above

If you would like to know more about the IOW centrifuge filter then please fill in the form below to get in contact with one of our team