The Eastern Gas Compression Roundtable is being held at David L. Lawrence Convention Center in Pittsburgh, PA, on May 3-5, 2022. IOW Group is exhibiting at Booth #603.

IOW Group is exhibiting at Easter Gas Compression Roundtable on May 3-5, 2022, in Pittsburgh, PA.

What is Eastern Gas Compression Roundtable?

The Eastern Gas Compression Roundtable (EGCR) has been held annually since 1973. Initially, with only a few hundred attendees, the event now boasts thousands of attendees and exhibitors from the US and internationally. The Eastern Gas Compression Roundtable is a non-profit organization, and the conference is promoted by those directly involved in the oil and gas industry. With the goal to provide training programs for entry-level through to advanced educational needs for industry-specific subjects, these programs are presented at the conference. Along with training programs, new innovative technologies, and knowledgeable speakers, the Eastern Gas Compression Roundtable is an opportunity to meet oil and gas industry professionals face to face to discuss changes and developments within the industry and new ideas regarding engine and compressor maintenance.

IOW Group's Mission

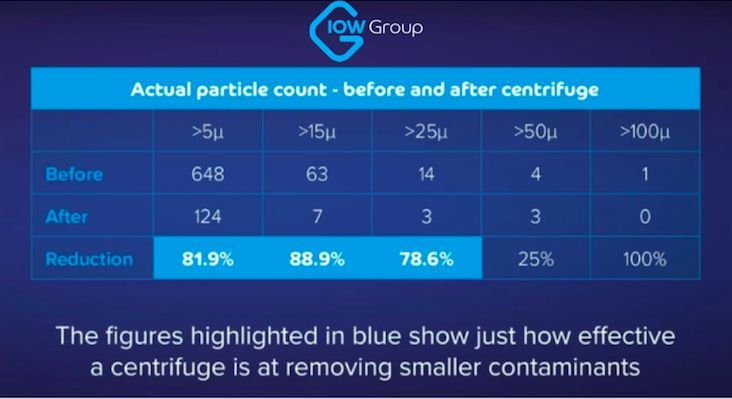

The IOW Group is an experienced and trusted manufacturer with over 100 years of combined experience in the lubrication sector. Our passion is to improve reliability and efficiency within organizations through our products. IOW centrifuges enhance the quality of lubrication oil by removing the maximum amount of contaminants. By utilizing unique patent-protected technology, the IOW centrifuge soil are 150% more efficient than any other centrifugal oil filter available!

Improving the quality of your lube oil by using a centrifugal filter can significantly impact processes within your organization.

- Reduced oil consumption

- Reduced machine downtime

- Reduced maintenance time

- Reduced man-hours

- Increased productivity

IOW Group centrifugal filters are designed for forward-thinking organizations who are searching for cleaner and more sustainable options to improve efficiency. If this sounds like you, then make sure to come and discuss how we can help you at Booth #603.

Would you like to learn more about how our products can help? Visit our installation webpage, where there are many case studies and installation bulletins available.

Cooper-Bessemer LS8G Engine:

A Natural Gas Compression Plant wanted to improve the reliability and productivity of their Cooper-Bessemer LS8G engine. Due to the engine lube oil pressure on these engines, the customer installed two (2) x IOW MP200 centrifuge filters.

After 557 run hours, the maintenance crew serviced the IOW MP200 centrifuge filters. The sludge cake collected was removed and weighed 819 grams (1.8 lbs), which is an excellent result for this short running time. The customer was extremely happy with the performance of the IOW MP200 centrifuge filters and will soon see the long-term rewards of upgrading the filtration system.

Read the full installation bulletin here

IOW MP200 Centrifuge Oil Filters removed 819g of contaminants in just 557 run-hours

A Natural Gas Compression plant installed four IOW MP600 centrifuge filters and a IOW Mechline triple screw pump to upgrade the filtration system

CAT GCM34 Engine :

This Natural Gas Compression Plant was looking to upgrade their filtration system to protect the CAT GCM34 engine from harmful contaminants in lube oil. By removing these particles from the oil, there is less wear on the engine components and, as a result, maintenance budgets can be dramatically reduced!

This CAT GCM34 gas compression engine, has a 1,500 Gallon reservoir and uses Mobil Pegasus 1005 lubrication oil. To effectively filter this large amount of oil, we supplied four (4) x IOW MP600 centrifuge filters and an IOW triple screw pump with a mechanical seal. This CAT GCM34 engine now has the best protection available from contaminants in oil; this will help increase productivity and extend the engine’s lifespan.

Find more installation results here

Centrifugal Oil Filters:

The IOW centrifuge is a centrifugal filter like no other. Redesigning a product previously not updated since the 1950s, our skilled team of engineers made the IOW centrifuge filter with various features to improve performance, reliability, and efficiency!

The IOW centrifuge filter has been designed to stop mixing of clean and dirty oil, with contaminated oil entering at the base and clean oil exiting through the top of the unit. This helps to avoid cross-contamination and means harmful particles do not enter back into circulation of the engine.

IOW Group's bypass centrifuge filters utilize unique bowl disc technology. Unlike conventional centrifugal spinners/separators, IOW Group centrifuge filters have a central bowl disc stack that increases the separation efficiency, dramatically reducing the time that contaminants stays in the oil.

The IOW range of centrifuges is patent protected and contains unique features to improve filtration performance

The bowl discs provide more surface area meaning finer separation and filtration can occur. Bowl disc dramatically speeds up the precipitation of the solids from the liquid.

IOW Group bypass centrifuge filters have dirt/sludge monitoring technology, which informs the operator when the separator needs servicing, saving valuable personnel time on, otherwise unnecessary, cleaning. The CentriClean remote monitor is Modbus or Bluetooth compatible and can be easily connected to your existing alarm systems. With the use of remote monitoring units, the user has the benefit of always being able to measure the centrifuges' performance and accordingly schedule services. This feature is not available with any other centrifuge filter and brings centrifugal technology to the 21st century!

IOW centrifuge filters allow you to maximize performance, extend maintenance intervals, and reduce the total cost of ownership (TCO) for engine systems and auxiliaries. IOW centrifuge filter comes standard with bowl disc technology and external monitoring for greater efficiency. Our centrifuge filters have also been designed to retrofit to existing pipework, so upgrading to this superior technology couldn’t be easier.

Our centrifugal technology is 150% more efficient than any competitors and provides superior protection for engines and auxiliaries from harmful contaminants.

Come and see one of our knowledgeable team at Booth #603 to find out more and discuss your requirements.

An IOW centrifuge filter removes the maximum amount of harmful contaminants from lube oil to protect engines from excessive wear

Triple Screw Pumps:

IOW Group manufactures a full range of positive displacement triple screw pumps to a higher standard than market-leading products to ensure durability. All IOW pumps fit within the industry-standard footprint for easy installation. There is a choice of standard mechanically sealed pumps. For a superior seal, IOW Group has a full range of magnetically sealed pumps suitable for both high and low temperatures.

The Magnaline pumps are magnetically sealed and completely leak-free, requiring very low maintenance keeping costs to a minimum. The pump installation is also very easy as there is no need to align the motor/pump.

Due to shaft seal design, mechanical pumps are financially more economical. The pumps are designed to be coupled directly to the electric motor, with pressure relief valve options. As well as complete pumps, we can also offer pump spares, a range of electric motors, and service kits for a wide variety of triple screw pumps.

IOW Group manufacture a full range of triple screw pumps with a choice of mechanical or magnetic seal.

If you are attending Eastern Gas Compression Roundtable (EGCR) 2022 and would like to discuss improving your pumping and filtration setup, then please visit our team at Booth #603.

Alternatively, fill in the contact form at the bottom of the page, and we will be in touch.

To learn more about Eastern Gas Compression Roundtable, visit EGCR.org

Contact the IOW Group

We will get back to you as soon as possible

Please try again later