The GMRC Gas Machinery Conference is being held at the Tampa Convention Center in Tampa, Florida from October 6-9, 2024. Join us to learn how we can help you increase engine reliability.

IOW Group is exhibiting at the Gas Machinery Conference.

What is GMRC Gas Machinery Conference?

The Gas Machinery Research Council (GMRC) was founded in response to the rapid expansion of natural gas pipeline facilities in the United States after World War II. The rapid growth of the natural gas industry allowed natural gas to flow quickly and smoothly through the pipelines. Compiled of proactive natural gas companies and professionals, the Gas Machinery Research Council (GMRC) is dedicated to investigating technical issues and finding innovative solutions to problems within the natural gas industry. The Gas Machinery Conference is an opportunity for face-to-face meetings with industry leaders to build strong relationships and discuss the most recent technology, news, and knowledge surrounding the natural gas industry. The Gas Machinery Research Council (GMRC) continues to lead the industry in advanced research and education opportunities, as well as providing a wealth of technical knowledge, making the Gas Machinery Conference one of the industry's premier events. The conference offers the chance to attend technical training and presentations on leading industry subjects. It showcases the most up-to-date technology and products that improve the reliability, efficiency, and cost-effectiveness of processes within the natural gas industry. IOW Group will be exhibiting at the Gas Machinery Conference with Sample Brothers at booth 908.

IOW Group's Mission

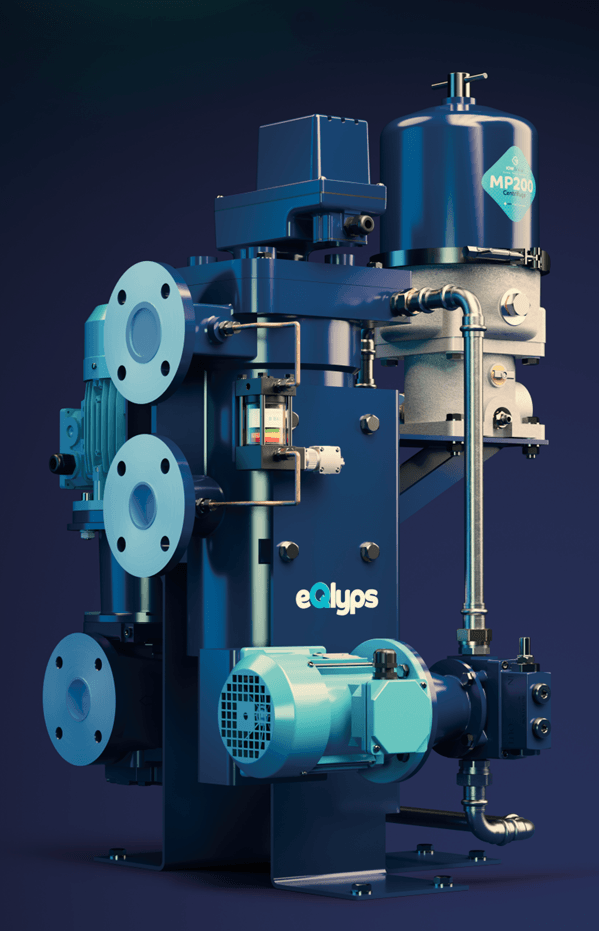

The IOW Group is an experienced and trusted manufacturer with over 100 years of combined experience in the lubrication sector. Our passion is to improve reliability and efficiency within organizations through our filtration products. We manufacture and supply our market-leading IOW MP centrifuges, triple screw pumps, and Q series backflushing filter. The IOW MP centrifugal filter and the IOW self-cleaning lube oil filter cleans oil to the highest standard currently available on the market. Combining all of IOW Group's products together into one solution creates our eQlyps complete filtration system. Within the newly-launched eQlyps complete filtration system, the IOW centrifuge enhances the quality of lubrication oil by removing contaminants down to the size of 1 micron. Utilizing unique patent-protected technology, the IOW centrifuge is 150% more efficient than any other centrifugal oil filter available! With the support of the IOW centrifuge, backflush filter, and backflush pump, each component will last longer and filter more effectively. The eQlyps filtration system is the most extensive oil cleaning solution currently available.

Improving the quality of your lube oil by using a centrifugal filter can significantly impact processes within your organization.

- Reduced oil consumption

- Reduced machine downtime

- Reduced maintenance time

- Reduced man-hours

- Increased productivity

IOW Group products are the next generation in oil filtration and are designed for forward-thinking organizations who are searching for cleaner and more sustainable options to improve efficiency. If this sounds like you, then make sure to come and discuss how we can help you at Stand 908.

Would you like to learn more about how our products can help? Visit our installation webpage, where there are many case studies and installation bulletins available.

Cooper-Bessemer LS8G Engine:

A Natural Gas Compression Plant wanted to improve the reliability and productivity of their Cooper-Bessemer LS8G engines. Due to the engine lube oil pressure on these engines, the customer installed two (2) IOW MP200 centrifuge filters.

After 557 run hours, the maintenance crew serviced the IOW MP200 centrifuge filters. The sludge cake collected was removed and weighed 819 grams (1.8 lbs.), which is an excellent result for this short running time. The customer was extremely happy with the performance of the IOW MP200 centrifuge filters and will soon see the long-term rewards of upgrading the filtration system.

Read the full installation bulletin here.

IOW MP200 Centrifuge Oil Filters removed 819g of contaminants in just 557 run-hours

By improving the cleanliness of the lubrication oil this CAT G3608 lifespan was tripled.

CAT G3608 Engine :

Engine lifespan was tripled when two (2) IOW MP200 centrifuge filters were installed at a Natural Gas compression Plant. The two centrifuge filters and CentriClean SCU0002 remote monitors were installed on a double mounting bracket on the inspection platform. The monitors display the current RPMs of the centrifuge filters and have the ability to set performance based alarms.

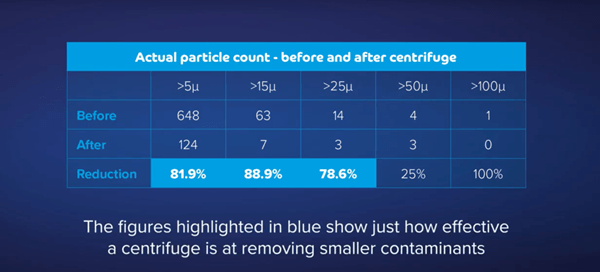

Oil analysis was conducted prior to the centrifuge installation, and the ISO oil cleanliness code was 22/19/11. After installing the IOW MP200 centrifuges, the ISO codes massively improved to 18/16/12!

When inputted into the Noria's life extensions table, the Caterpillar G3608 engine lifespan had tripled! Creating significant savings and increased reliability for this Natural Gas Compression Plant.

Read the full case study here.

eQlyps complete filtration solution

Combining our new Q series backflushing filter, backflush pump, and market-leading MP centrifuge with remote monitoring technology means our customers receive the highest level of filtration performance currently available with the IOW Group eQlyps complete filtration solution.

Our new Q series backflushing filter is the next generation of backflushing filtration. It has been manufactured from much stronger and more durable components to enhance its filtration capabilities. The eQlyps comes fitted with a backflush pump which increases the flow and pressure to support the filtration process.

More slimline and compact than other options, the eQlyps system is perfect for small spaces or cramped environments due to its small footprint.

Combining backflushing filtration and centrifugal filters allows our customer to filter their oil down to 1 micron using the eQlyps complete filtration system. With the support of the centrifuge, backflush filter, and backflush pump, each component will last longer and filter more effectively. This results in extended engine lifespan, longer oil change intervals, and reduced maintenance required.

eQlyps self-cleaning lube oil filter launched in September 2022, and IOW Group is the only manufacturer worldwide to offer this complete system.

The IOW eQlyps complete filtration system combines backflushing and centrifugal filtration technology to remove particles down to 1 micron.

Centrifugal Oil Filters:

The IOW centrifuge is a centrifugal filter like no other. Redesigning a product previously not updated since the 1950s, our skilled team of engineers made the IOW centrifuge filter with various features to improve performance, reliability, and efficiency!

The IOW centrifuge filter has been designed to stop mixing clean and dirty oil, with contaminated oil entering the base and clean oil exiting through the top of the unit. This helps to avoid cross-contamination and means harmful particles do not enter back into the circulation of the engine.

IOW Group's bypass centrifuge filters utilize unique bowl disc technology. Unlike conventional centrifugal spinners, IOW Group centrifuge filters have a central bowl disc stack that increases the separation efficiency, dramatically reducing the time contaminants stay in the oil.

The IOW centrifuge filters are patent protected and contains unique features to improve filtration performance.

The bowl discs provide more surface area meaning finer separation and filtration can occur. Bowl disc dramatically speeds up the precipitation of the solids from the liquid.

IOW centrifuge filters allow you to maximize performance, extend maintenance intervals, and reduce the total cost of ownership (TCO) for engine systems and auxiliaries. IOW centrifuge filter comes standard with bowl disc technology and external monitoring for greater efficiency. Our centrifuge filters have also been designed to retrofit to existing pipework, so upgrading to this superior technology couldn’t be easier.

Our centrifugal technology is 150% more efficient than any competitors and provides superior protection for engines and auxiliaries from harmful contaminants.

Come and see one of our knowledgeable team at Stand 908 to find out more and discuss your requirements.

An IOW centrifuge filter removes the maximum amount of harmful contaminants from lube oil to protect engines from excessive wear.

Triple Screw Pumps:

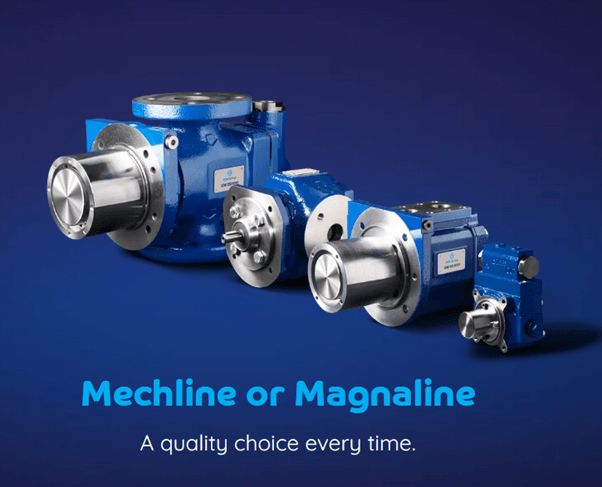

IOW Group manufactures a full range of positive displacement triple screw pumps to a higher standard than market-leading products to ensure durability. All IOW pumps fit within the industry-standard footprint for easy installation. There is a choice of standard mechanically sealed pumps. For a superior seal, IOW Group has a full range of magnetically sealed pumps suitable for high and low temperatures.

The Magnaline pumps are magnetically sealed and completely leak-free, requiring very low maintenance and keeping costs to a minimum. The pump installation is also straightforward as there is no need to align the motor/pump.

Due to shaft seal design, mechanical pumps are financially more economical. The pumps are designed to be coupled directly to the electric motor, with pressure relief valve options. As well as complete pumps, we can also offer pump spares, a range of electric motors, and service kits for a wide variety of triple screw pumps.

IOW Group manufacture a full range of triple screw pumps with a choice of mechanical or magnetic seal.

If you are attending GMRC Gas Machinery Conference and would like to discuss improving your pumping and filtration setup, then please visit our team at Stand 908.

Alternatively, fill in the contact form at the bottom of the page, and we will be in touch.

Contact the IOW Group

We will get back to you as soon as possible

Please try again later