Industry: Trucking

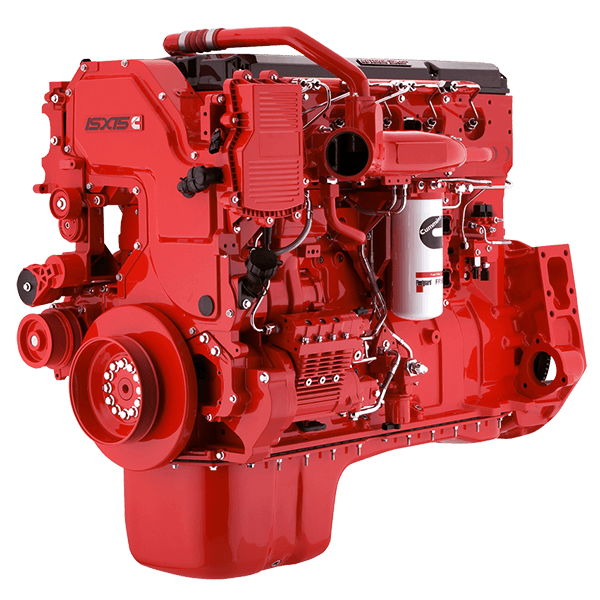

Engine: Cummins ISX 15

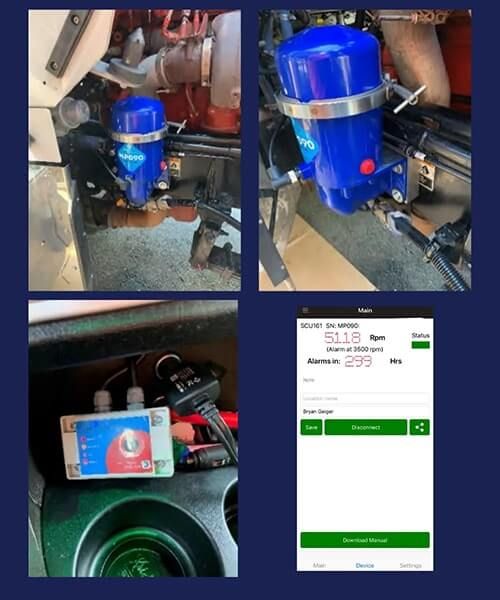

Model Installed: IOW MP090 Bypass Centrifuge Filter & CentriClean SCU0003 Remote Monitor

A Kenworth truck with a Cummins ISX 15 engine had an IOW MP090 bypass centrifuge installed alongside a CentriClean SCU0003 remote monitor

A Brief History:

Cummins Inc is an American multinational corporation specializing in the design, manufacture, and distribution of diesel and alternative fuel engines, generators, and related technology. The Cummins ISX series first debuted in 2001 and the Cummins ISX 15 is one of the most popular models for heavy-duty engines in North America. The engine delivers impressive fuel economy but with extreme horsepower. The Cummins ISX 15 engine boasts ratings from 400-600 horsepower and is manufactured to maximize performance and durability. The Cummins ISX series of engines is highly adaptable to a wide variety of needs making it popular amongst drivers and fleet operators.

The Cummins ISX 15 is a popular engine in the US trucking industry

The Installation

The driver of a 2017 Kenworth truck in the USA wanted to improve the filtration of the engine oil for his Cummins ISX 15 engine. The truck driver uses 15W-40 lubrication oil and Max Mileage Fuel Borne Catalyst fuel additive. Removing the maximum amount of contaminants from the oil means the engine will run smoother for longer.

At 65 MPH, the oil pressure on this Cummins ISX 15 is 42 PSI (2.9 Bar). The CentriClean App illustrates 5,118 RPMs.

The IOW MP090 centrifuge filter and CentriClean SCU0003 monitoring unit are the most suited for this Cummins ISX 15. Once installed, the driver connects to the CentriClean App via Bluetooth. This links to the CentriClean SCU0003 monitoring unit to provide live data on the running status of the centrifuge filter. The CentriClean App provides RPM information, run-hours and has the ability to schedule alarms based on the time or performance of the centrifuge. The driver can also access manuals and even order spares through the app, all available through his smartphone or tablet for ease of use.

The IOW MP090 bypass centrifuge was installed with a CentriClean SCU0003 to protect the Cummins engine was excessive wear

The Results

After 18,000 miles driven, the IOW MP090 bypass centrifuge filter was removed to see how much sludge cake had gathered on the outer centrifuge bowl wall. The soot and contaminants measured 32mm thick (1/8 inch). This was removed, and a new paper insert was installed.

The truck driver continued driving for another 70,000 miles before servicing the IOW MP090 centrifuge filter. After this duration, the IOW MP090 centrifuge removed 113.4 grams (4oz) of harmful contaminants!

Removing these abrasive particles means the trucker is protecting the future of his biggest investment...His truck engine! Maintenance requirements are reduced, engine efficiency is increased, and the total cost of ownership (TCO) is lowered!

The central bowl disc stack inside the IOW MP090 centrifuge filter speed up the separation process and helps draw out finer particulate

The Products:

The IOW MP090 Centrifuge Filter

The IOW MP090 centrifuge filter has been designed for an oil sump capacity of 15-90 liters (3.3-20 gallons). The IOW centrifuge filter turns faster than any existing market product creating a faster and better separation process. The higher speeds of the IOW centrifugal filter separate solids from the lubrication oil more effectively than any other centrifugal oil filter on the market.

The IOW centrifuge bowl is completely sealed, avoiding any cross-contamination between cleaned and dirty oil. The IOW MP090 centrifuge filter has a central disc stack, which significantly improves the efficiency of the separation process. Combining these unique features makes the IOW centrifuge oil filter 150% more efficient than any currently available product. All these features of an IOW centrifuge filter are patent protected; therefore, they are only available through the IOW Group.

The IOW MP090 bypass centrifuge filter is suitable for a sump capacity of 15-90 liters and is available with a choice of remote monitoring

The CentriClean SCU0003 Remote Monitoring Unit

The

CentriClean SCU0003 remote monitoring unit is designed to monitor the performance of the centrifuge. This particular model is ideal for those operators who want access to live data at their fingertips! Using the

CentriClean App, users can connect via Bluetooth to the SCU unit to access information and data.

Within the CentriClean App, the operator can see the speed of the centrifuge (RPM), set alarms for run-hours completed or if there is a drop in performance, or if servicing may be required. Multiple CentriClean SCU0003 units can be connected to the app, making it easy to set, control, and log the centrifuges without physically seeing each centrifuge. Manuals are also available with the CentriClean App, where you can place orders for spare parts directly with us. Notes can be placed within each SCU profile on the app, making it easy to communicate within a team. Remote monitoring uses fewer resources and ensures higher performance from your centrifuge. The IOW centrifuges are the only product of their kind to offer a choice of remote monitoring units.

The CentriClean SCU0003 monitoring unit connects via Bluetooth to the CentriClean App to ensure optimal performance of the centrifuge

Contact the IOW Group

We will get back to you as soon as possible

Please try again later