Industry: Marine

Engine: MAN 6L23/30H Engine

Model Installed: IOW MP200 Centrifuge filter & CentriClean SCU0002 monitoring unit

The IOW MP200 centrifuge filter were installed onboard this Maersk vessel

A Brief History:

MAN marine engines have incredibly economical fuel consumption with powerful acceleration. Developing their first diesel engine in 1897, MAN is a well-known and trusted engine manufacturer. The MAN 6L23/30H engine has been a customer favorite for over five decades! First introduced in the mid-60s, the MAN 6L23/30H is a four-stroke diesel engine with six cylinders and is stable, reliable, and cost-efficient. The MAN 6L23/30H has a well-earned reputation for easy maintenance and the longest time between overhauls in its class. The classic design and robust structure of the MAN 6L23/30H make it perfect for the marine industry.

The MAN 6L23/30H engine is stable, reliable, and cost efficient.

The Installation:

We were excited to show off the superior performance of the IOW centrifuge range onboard the tanker Maersk Kara. Looking to upgrade from their old centrifugal technology to improve the lube oil cleanliness, the best model for the job was the IOW MP200 oil centrifuge, and the results did not disappoint!

The vessel had an MAN 6L23/30H engine fuelled by distillate and HFO (Heavy Fuel Oil) running at 4 bar pressure (58 PSI). The MAN 6L23/30H engine had an oil capacity of 400-500 liters (88- 110 Gallons), and Maersk was using TARO 30 DP 30 lube oil at 58°C (136°F). The oil was changed based on oil analysis results and the contaminant levels found in the lube oil.

The IOW range of oil centrifuges are designed to be fully interchangeable with current products on the market. This means it retrofits to existing mountings without any modifications needed. This made the installation of the IOW MP200 oil centrifuge quick and easy. Once the IOW MP200 oil centrifuge was installed, the CentriClean SCU0002 displayed on the front screen the centrifuge was turning at 5802 RPM.

The IOW MP200 oil centrifuge was retro-fitted to replace old centrifugal technology and improve oil cleanliness.

The Results

The IOW MP200 had been successfully installed to replace the old centrifugal technology. Running at around 5802 RPM, the oil centrifuge continuously cleaned the lube oil for 200 run-hours.

After 200 run-hours, the IOW MP200 was removed for cleaning. Samples were taken for oil analysis to ensure the lube oil was still fit for purpose. After a relatively short run time, the IOW MP200 oil centrifuge had already collected sludge with a thickness of 22mm!

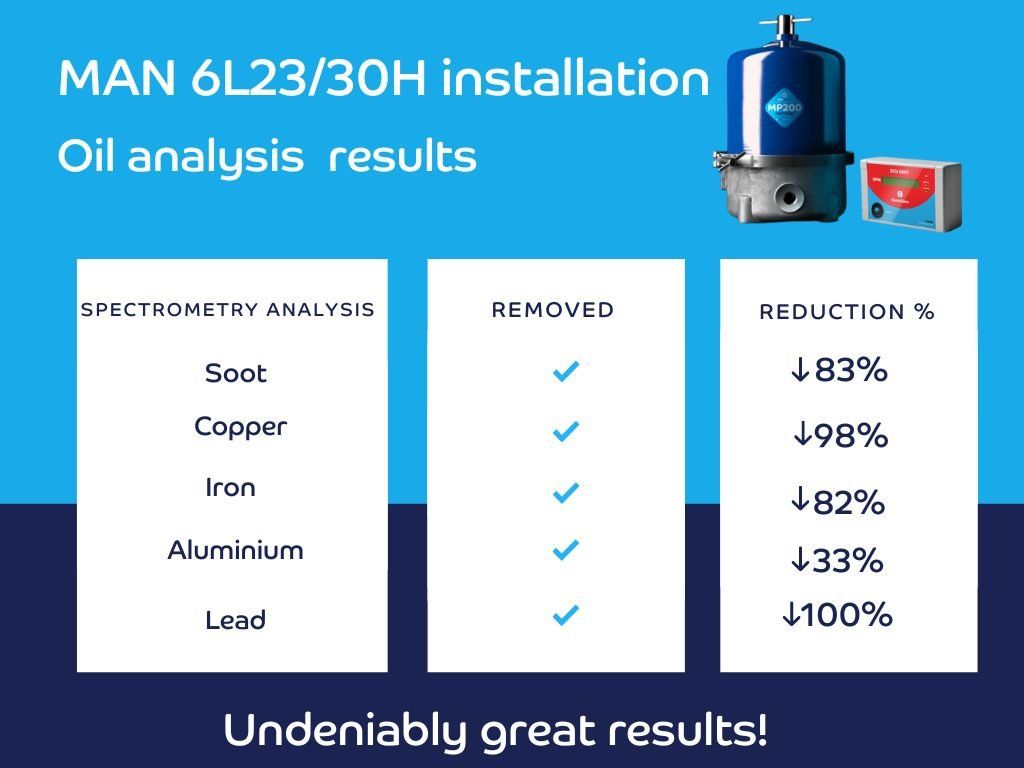

However, the real reward was the results from the oil analysis. The oil cleanliness had dramatically improved and showed huge reduction in the lube oil contaminants.

Oil analysis reports showed an 83% reduction in soot in the oil after being cleaned by the IOW MP200 centrifuge. Copper had reduced by 98%, iron levels dropped by 82%, 33% less aluminum was present, and lead particles were completely eradicated.

The oil was still fit for purpose, and the customer was happy with the performance of their new IOW oil centrifuge. In the long term, this customer will see more benefits and cost savings due to upgrading their centrifugal technology.

After 200 run-hours the IOW MP200 had drawn out sludge and contaminants the measured 22mm thick.

Oil analysis results shows a dramatic reduction in various contaminants

The Products:

The IOW MP200 Centrifuge Filter

The IOW MP200 centrifuge filter has been designed for an oil sump capacity of 35-175 liters. The IOW centrifuge filter turns faster than any existing market product creating a faster and better separation process. The higher speeds of the IOW centrifugal filter separate solids from the lubrication oil more effectively than any other centrifugal oil filter on the market.

The IOW centrifuge bowl is completely sealed, avoiding cross-contamination between cleaned and dirty oil. The IOW MP200 centrifuge filter has a central disc stack, which significantly improves the efficiency of the separation process. Combining these unique features makes the IOW centrifuge filter 150% more efficient than any other currently available product. All these features of an IOW centrifuge filter are patent protected and, therefore, only available through the IOW Group.

The CentriClean SCU0002 Remote Monitoring Unit

The CentriClean SCU0002 is designed to monitor the performance of the centrifuge. During its regular operation, it will continuously display the current RPMs of the centrifuge and monitor run hours. Alarms can be set to alert the operator when run hours have been completed or if the performance of the IOW centrifuge reduces. Having alarm systems in place saves on precious man-hours, helps utilize fewer resources, and ensures your filtration system is working to the best of its ability.

The CentriClean SCU0002 monitoring unit is Modbus compatible with existing systems. The unit requires 12-24 volts DC to operate and is provided via the power terminal block. The centrifuge filter sensor is a 3-wire device and requires +5 volt supply.

The IOW MP200 centrifuge oil filter is suitable for a sump capacity of 35-175 liters and is available with a choice of remote monitoring

The CentriClean SCU0002 monitoring unit displays live RPMs of the centrifuge on the front screen.

Contact the IOW Group

We will get back to you as soon as possible

Please try again later