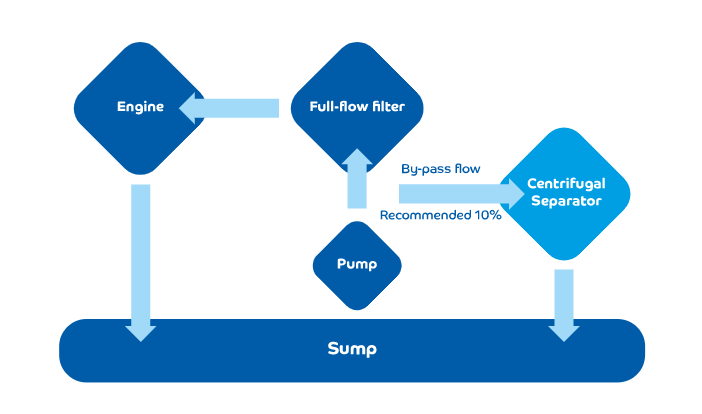

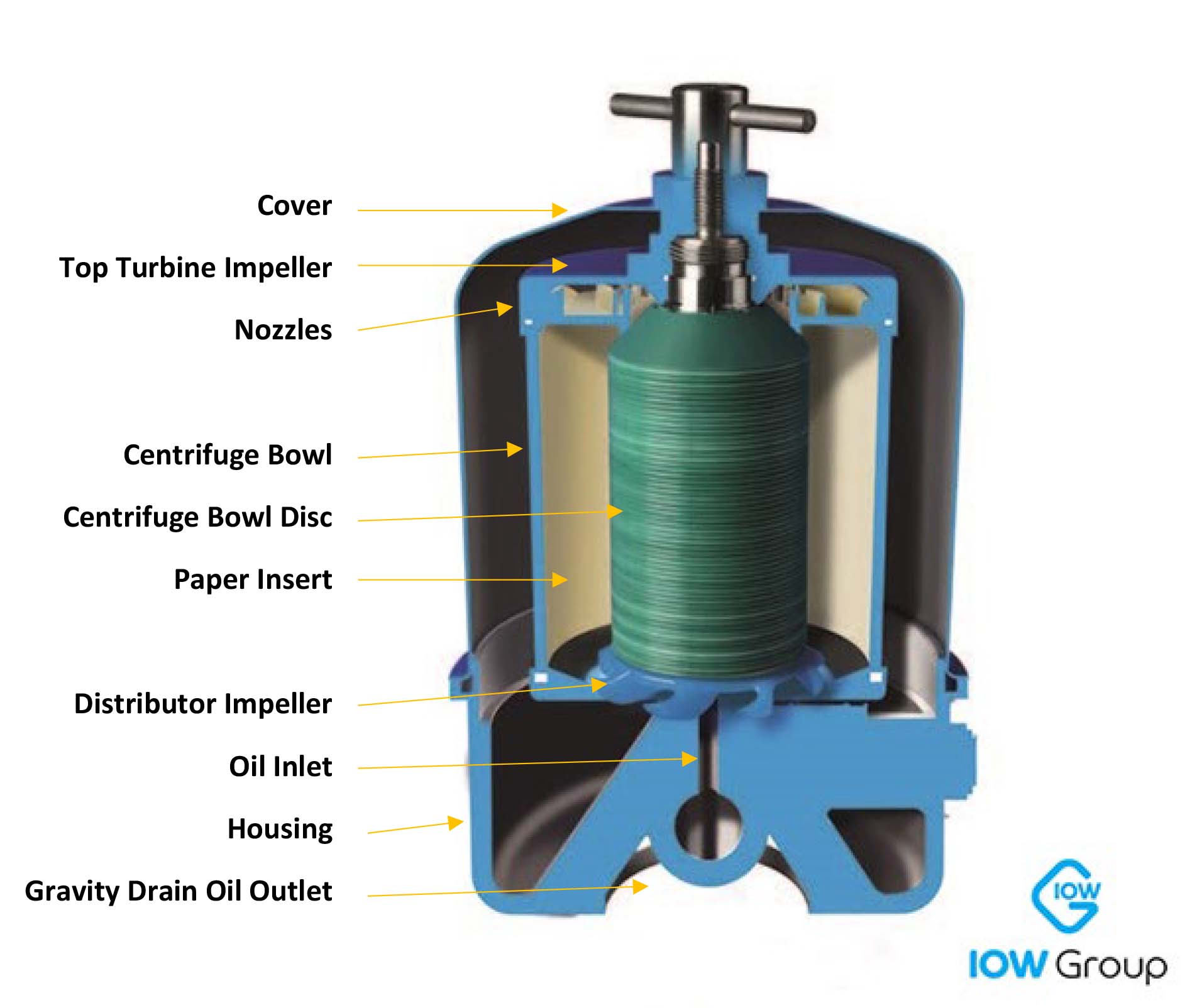

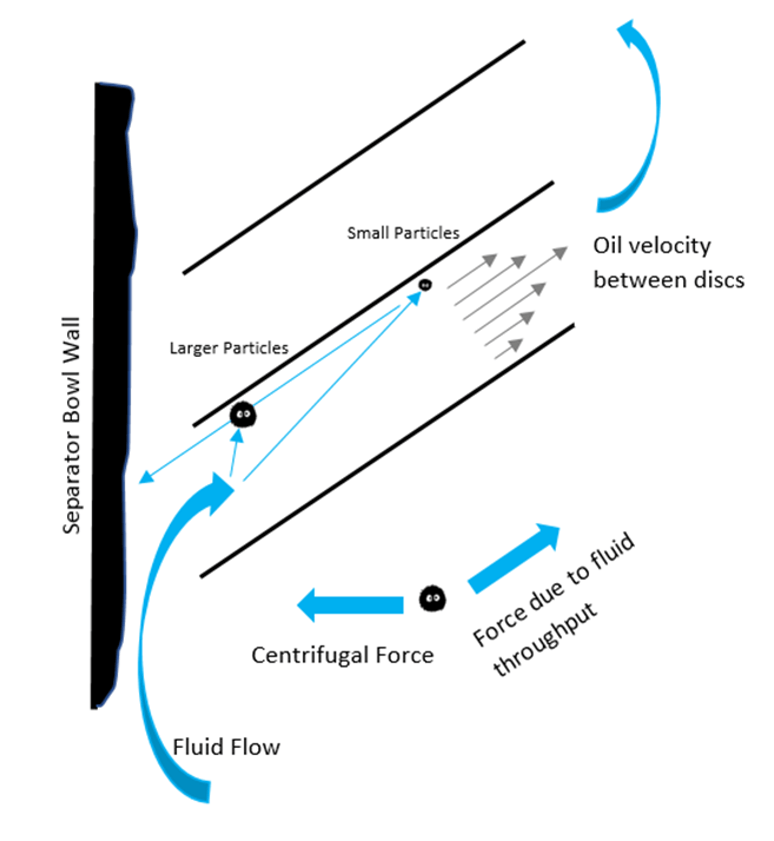

Because of the inline full-flow filters, the larger particles found in the fluid medium cannot pass through the perforated layers of filter media. However, fluids and particles smaller than the full-flow filter mesh can still pass through the filter mesh under pressure, vacuum, or gravitational force. A centrifugal oil filter is essentially a type of bypass oil filter that processes a small percentage of the oil flow so as not to starve the machinery of oil and sometimes cause irreparable damage. Unlike other filtration processes, with centrifugal filtration, there are no filter media, the unit is not disposable, and in some cases, the centrifuge can remove particles even as tiny as nanoparticles.

Users of a single filter system to clean oil are familiar with the cycle of inconsistent oil cleaning quality, replacement of filter elements, the disposal of oil and filter elements, and purchasing and storing new filter elements. A standard cartridge filter system works to capture particles that are larger than the filter mesh. There is an upper limit to ideal cleaning effectiveness: as the filter begins to reach its capacity, its cleaning efficiency will decrease. The previously collected contaminants will be released whenever the filter experiences pressure shocks due to start and stop conditions. As soon as a filter is full and no longer completing its duty, filter elements must be disposed of and replaced with new ones.