Industry: Trucking

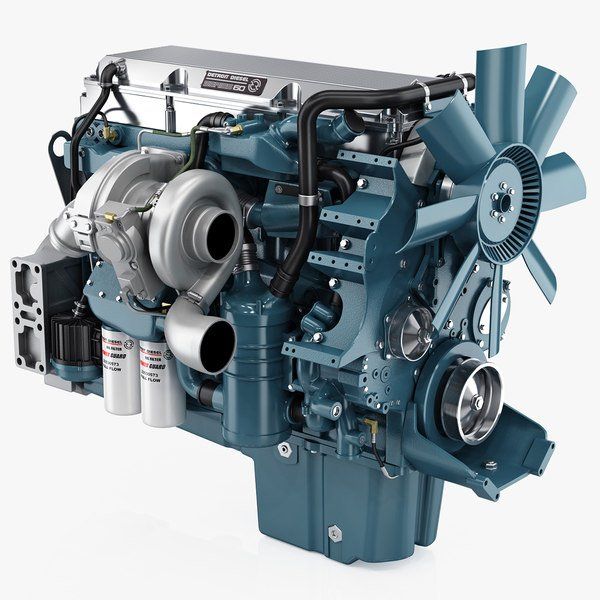

Engine: Detroit Series 60

Model Installed: IOW MP090 Bypass Centrifuge Filter & CentriClean SCU0003 Remote Monitor

A Freightliner with a Detroit Series 60 engine had an IOW MP090 oil centrifuge installed to assist with the quality of the engine oil

A Brief History:

The Detroit series 60 engine is a 4 stroke diesel engine that was originally produced in 1987. Since 1992 the engine has been North America's most popular heavy-duty diesel engine for use on the highway, selling more than 1.2 million units since being manufactured. It was the first Detroit engine with fully integrated electronic controls. The DDEC (Detroit Diesel Electronic Control System) allows owners to troubleshoot engine problems, shutdown timers, load fault history, prevent stalling; and also includes cruise control capabilities, which are very popular due to their fuel-saving capabilities. The DDEC system is easy to operate, and diagnostics are displayed to the driver.

The Installation

A truck driver wanted to improve the quality of engine oil supplying his Detroit Series 60 engine. The engine was fitted on a 1994 Freightliner using Chevron Delo 400 SAE 15W-40 lubrication oil. By upgrading the filtration system on this truck, more harmful contaminants will be removed, and improve the lubrication oil. Additionally, this engine will benefit from reduced maintenance costs and increased reliability.

The IOW centrifuge oil filter model suitable for the Detroit Series 60 engine is the IOW MP090 centrifugal bypass filter with the CentriClean SCU0003 remote monitor (Separator Control Unit). The IOW MP090 centrifuge filter was easily fitted to an existing mount on the Freightliner.

The CentriClean SCU0003 control panel has been designed with mobile device users in mind and is perfect for truckers that are always on the move! Using Bluetooth, the driver connects to the CentriClean App to set up a centrifuge profile, where you then obtain real-time data and measure the performance of the IOW MP090 centrifuge filter.

The Detroit Series 60 engine is one of the most popular heavy duty engines for use on the highway

The IOW MP090 bypass centrifuge connects to the CentriClean App via Bluetooth to provide access to live real-time data

The Results

Once the IOW MP090 centrifuge oil filter was installed, the driver continued working. As this Freightliner drove up and down the highway delivering goods and services, the IOW MP090 centrifuge filter began removing contaminants from the engine oil.

After 12,000 miles driven, the IOW centrifuge oil filter was removed for servicing. The contaminants collected on the outer centrifuge bowl wall were removed and weighed 227 grams (8oz)! The driver continued as usual and drove a further 12,500 miles. The IOW MP090 centrifugal bypass filter had drawn out even more harmful contaminants than the initial 12,000 miles driven. The soot collected weighed a fantastic 414 grams (14.6oz)! This was over a duration of 350 run driving hours. This calculates to a dirt removal rate of 1.19 grams per hour!

The IOW range of centrifugal oil filters spins 15-30% faster than any other product currently on the market. Due to the increased centrifugal force created, the sludge cake is forced to the outer bowl wall and hardens into a rigid shell. This installation was a perfect example of this increased force and pressure, as seen in the pictures to the right. This hardened sludge casing had formed after 14,978 miles driven over a duration of 403 run-hours of the IOW MP090 centrifuge filter.

Without using the IOW MP090 bypass filter, the harmful particles within the lube oil would have caused excessive wear and damage to this Detroit Series 60 engine. This trucker has installed the superior IOW centrifuge oil filter, which has helped reduce the maintenance expense and increased the engine's lifespan.

Without using the

IOW MP090 bypass filter, the harmful particles within the lube oil would have caused excessive wear and damage to this Detroit Series 60 engine. Having installed the superior IOW centrifuge filter, this trucker has helped reduce the maintenance expense and increased the engine's lifespan.

The contaminants in the engine oil are drawn out to the outer bowl wall and forms a hardened sludge cake that can be easily disposed of

The Products:

The IOW MP090 Centrifuge Filter

The IOW MP090 centrifuge oil filter is designed for an oil sump capacity of 15-90 liters (3.3-20 gallons). The IOW centrifuge filter turns faster than any existing market product creating a faster and better separation process. The higher speeds of the IOW centrifugal filter separate solids from the lubrication oil more effectively than any other centrifugal oil filter.

The IOW centrifuge bowl is completely sealed, avoiding cross-contamination between cleaned and dirty oil. The IOW MP090 centrifuge filter has a central disc stack, which significantly improves the efficiency of the separation process. Combining these unique features makes the IOW centrifuge oil filter 150% more efficient than any available product. All these features of an IOW centrifuge filter are patent protected; therefore, they are only available through the IOW Group.

The IOW MP090 centrifugal oil filter is suitable for a sump capacity of 15-90 liters and is available with a choice of remote monitoring

The CentriClean SCU0003 Monitoring Unit

The CentriClean SCU0003 remote monitoring unit is designed to monitor the performance of the centrifuge. This model is ideal for those operators who want access to live data at their fingertips! Using the CentriClean app, users can connect via Bluetooth to the SCU unit to access information and data.

Within the

CentriClean App, the operator can set the speed of the centrifuge (RPM), set alarms for run-hours completed or if there is a drop in performance, or if servicing may be required. Multiple

CentriClean SCU0003 units can be connected to the app, making it easy to set, control, and log the centrifuges without seeing each centrifuge physically. Manuals are also available with the

CentriClean App, where you can place orders for spare parts directly with us. Notes can be placed within each SCU profile on the app, making it easy to log data for future reference. Remote monitoring uses fewer resources and ensures higher performance from your centrifuge. The IOW centrifuges are the only product of their kind to offer a choice of remote monitoring units.

The CentriClean SCU0003 monitoring unit connects via Bluetooth to the CentriClean App to ensure optimal performance of the centrifuge