Industry: Natural Gas Compression

Engine: Cooper-Bessemer LS8G

Model Installed: 2 x IOW MP200 Centrifuge Filter & CentriClean SCU0002 Remote Monitor

The IOW MP200 centrifuge filter was installed at a natural gas compression plant to improve reliability and productivity.

A Brief History:

Originally starting out only manufacturing farming equipment Cooper-Bessemer is now known to make some of the most reliable and efficient engines for gas compression. An excellent brand for industrial engines and compressors, the Cooper-Bessemer can accommodate extreme variations in operating pressures and flow rates. The Cooper-Bessemer LS-G series has a rated speed of 360 RPM and can have up to 8 power cylinders. Cooper-Bessemer power engines are rated up to 8700 hp (6486 kW).

The Cooper-Bessemer LS8G engine is a popular model in natural gas compression

The Installation

A Natural Gas Compression Plant wanted to improve the reliability and productivity of their Cooper-Bessemer LS8G engine. At this gas compression plant, the oil temperature is 153.7° F (67.6 °C), and the oil pressure is 36 PSI (2.48 bar). Due to the engine sump size at the gas compression plant, the customer installed two (2) x IOW MP200 centrifuge filters.

The IOW centrifuge filter removes the maximum particulate from the lube oil. As a result our customer avoids unexpected downtime and reduces man-hours (and budget) spent on maintenance of the engine and machinery.

2 x IOW MP200 centrifuge filters were installed at the natural gas compression plant

The Results

At 36 PSI (2.48 bar) lube oil pressure, the CentriClean SCU0002 monitor displayed the RPMs of the IOW MP200 centrifugal oil filters at 4,000 RPMs. The IOW centrifuge spins 15-30% faster than any other spinner type separator available. The increased bowl speed generates increased centrifugal force aiding more effective solids separation in the lube oil. This huge force pushes particles out of the oil and to the outer bowl wall, ready for disposal.

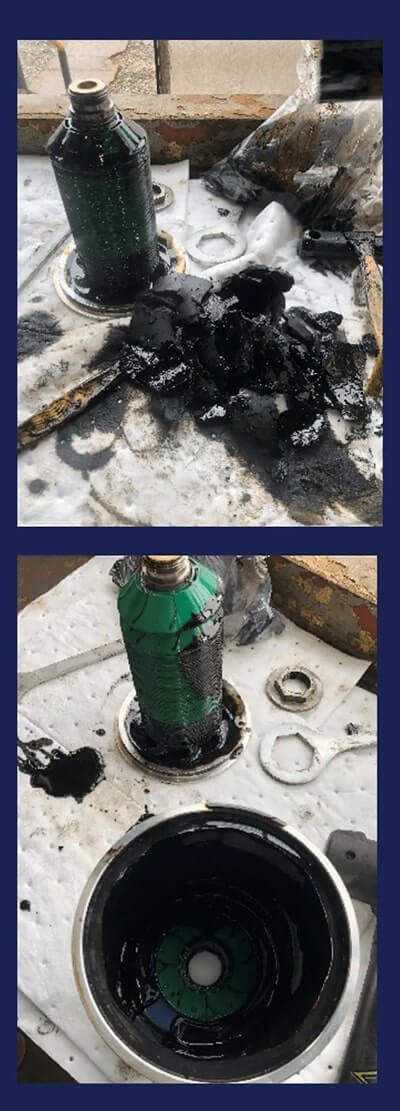

After 557 run hours, the maintenance crew serviced the IOW MP200 centrifuge filters. Before the sludge cake could be removed from the centrifuge bowl the central disc stack has to be taken out (see pictures). The bowl discs are unique to the IOW centrifugal oil filter and are an integral part in the filtration performance of the IOW centrifuges. The bowl disc stack provides a larger surface area for the separation process resulting in even the smallest contaminants being drawn out from the lube oil, pushed through the bowl disc stack, and forced onto the outer bowl, wall ready for collection.

The sludge cake collected was removed and weighed 819 grams (1.8 lbs), which is an excellent result for this short running time (557 hours). The customer was extremely happy with the performance of the IOW MP200 centrifuge filters and will soon see the long term rewards of upgrading the filtration system.

After 557 run hours 819grams of sludge was collected in the centrifuge filter.

The Products

The IOW MP200 Centrifuge Filter

The IOW MP200 centrifuge filter has been designed for an oil sump capacity of 35-175 liters. The IOW centrifuge filter turns faster than any existing market product creating a faster and better separation process. The higher speeds of the IOW centrifugal filter separate solids from the lubrication oil more effectively than any other centrifugal oil filter on the market.

The IOW centrifuge bowl is completely sealed avoiding any cross contamination between cleaned and dirty oil. The IOW MP200 centrifuge filter has a central disc stack, which significantly improves the efficiency of the separation process. Combining these unique features makes the IOW centrifuge filter 150% more efficient than any other currently available product. All these features of an IOW centrifuge filters are patent protected therefore only available through IOW Group.

Contact the IOW Group

We will get back to you as soon as possible

Please try again later