Location: Ecuador

Industry: Power Generation

Engine Type: Hyundai Himsen 9H21/32

Model Installed: IOW MP600 centrifuge filter

Background Info

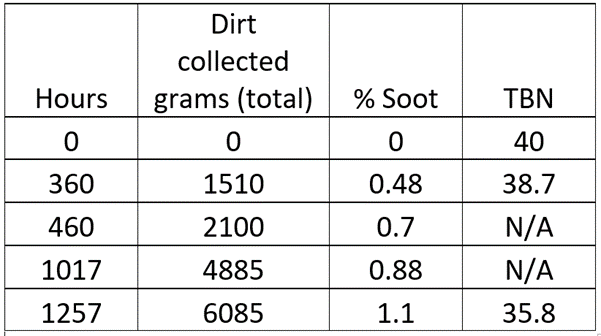

A Power Plant customer in South America approached us wanting to explore cost savings that could be achieved using the IOW MP centrifuge filter. The main objective was to increase the oil change intervals by maintaining insoluble levels- including soot- below 1%, and by protecting the TBN (Total Base Number) level of the oil.

By extending the oil change interval and lowering contaminants in the oil, the IOW centrifuge filter would not only achieve cost savings by consuming less oil but also by protect the engine components from excessive and unnecessary wear. These cost savings would mean that less operating budget be required for maintenance.

South American Power Plant explores the benefits of an IOW centrifuge filter

Installation

After discussing specifications and requirements with the customer, it was agreed the IOW MP600 would be the most suitable centrifuge filter model for their Hyundai Himsen 9H21/32 engines. The old centrifugal separators were Mann+Hummel FM600 centrifuge filters, this meant the installation process was simple due to the interfaces being identical.

The new centrifuge filter was mounted on a flange from the inspection platform with a large gravity drain pipe. The pipe features an elbow and flexible hose with an isolation valve and pressure gauge to supply the pressurized lubrication oil to the centrifuge inlet directly from the engine's pump.

The Results

As the IOW MP600 centrifuge filter runs at a speed of approximately 4,300 rpm, after just 200 hours of operation, the centrifuge filter had removed 1,730 grams of contaminants from the lube oil! This translates into a dirt removal rate of 8.7 grams per hour!

To accurately assess the performance of the IOW centrifuge filter and the impact of the higher removal rate on the lube oil, the oil was changed and the IOW MP600 centrifuge filter was cleaned.

IOW MP600 centrifuge filter installed at a power plant

Customer Feedback

The previously installed Mann+Hummel centrifuge filters would only operate for around 700 hours before insoluble levels were higher than the desired 1%. As a result, the lubrication oil would then be changed.

The IOW MP600 centrifuge filter managed to more than double the oil change interval for this customer! The 1% insoluble limit was reached after a massive 1,500 hours! In addition, TBN (The Base Number) levels remained acceptable with only a 10% reduction on new lube oil levels.

Inside an IOW MP600 centrifugal separator, showing thick dirt build-up on the outer wall and bowl disc stack for more effective filtration.

Conclusion

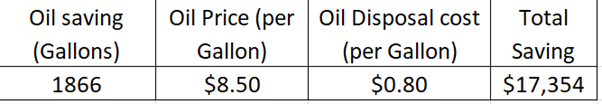

This installation showcased great results for the IOW centrifuge filter in comparison to the old centrifugal separator technology. By more than doubling the oil change intervals, the customer now saves on engine downtime, labor rates, and maintenance costs.

Ultimately, the annual savings made by extending the oil change intervals are massive.

It was calculated at the time of publication, that on an average of 7,000 operating hours with oil costing $8.50/gallon and disposal cost of $0.80/gallon, the IOW centrifuge filter would save this customer $17,354.

Following the fantastic results and positive feedback from the customer, the decision was made to fit all the Hyundai Himsen 9H21/32 engines on their site with IOW MP600 centrifuge filters.

The superior centrifugal separation power of the IOW Group centrifuge filters will maximize savings and productivity throughout the power plant.

To find out how IOW Group could help increase efficiency within your organization, complete the contact form at the bottom of the page and one of our team will be in touch!

Contact the IOW Group

We will get back to you as soon as possible

Please try again later