After cruising the open road for hundreds, even thousands of miles, contaminants in the lubrication oil of your truck engine are inevitable! Soot, dust, and particulate caused through abrasive motions are all unavoidable in the trucking industry. Even brand new oil already contains particles that will damage your engine. That’s why effective filtration is absolutely essential in the care and maintenance of your truck, and one of the best forms of removing these harmful contaminants is a bypass centrifugal filter for your truck engine.

The IOW MP090 bypass centrifugal filter comes with a choice of remote monitoring (SCU) units and can retro-fit to existing pipework

Why does my diesel engine need additional filtering?

Diesel trucks come with a primary filter as standard. These only filter down to (a maximum) 10 μm sized particles, but it’s the smaller (less than 10 microns) particulate which can cause havoc within your engine. The tiny contaminants get in the smallest of spaces causing abrasion, blockages, and will affect the performance of your engine. Even the most modern and efficient engines can be stopped in their tracks by lubrication oil laden with contaminants. Lube oil is a crucial aspect of truck engine life and needs to be treated as the lifeblood of your engine to maintain a healthy and clean circulation! Without effective lubrication, the engine components are under increased pressure and the engine will slow and eventually seize up.

All too often, oil changes are done with the thinking that this is will ensure a clean engine and healthy lubrication system. However, even new oil is filled with harmful particles; not only does this not result in clean oil being circulated, but it is also a very costly option and increases your maintenance budget dramatically. Effective filtration is crucial in removing these engine killers and is the only option to achieve worthwhile lubrication and protection for your engine. Powerful filtration from an

IOW bypass centrifugal filter will hugely reduce the contaminants and help to extend oil change intervals. This reduces the total cost of ownership (TCO), is kinder to the environment, and reduces the amount of maintenance required on the engine.

How to improve fuel efficiency

For optimal fuel efficiency, your truck engine would benefit from having a primary filter and a bypass-style secondary filter. So it makes sense that the truck engines' filtration system is of high priority. Bypass filters are secondary filters taking a small percentage of the lubrication oil to clean before returning it to the main sump. They purify the oil continuously. Bypass filters tackle particles smaller than 10 microns helping to ensure that your truck runs smoother for longer.

How does a bypass centrifuge filter work?

The bypass centrifugal filter is considered the most efficient type of secondary filter you can install, harnessing centrifugal force to draw out the sub-micron particles. IOW Group has designed the next generation of centrifugal bypass filters that are also available with a choice of remote monitoring units to measure the performance of your centrifuge filter.

With an IOW centrifugal bypass filter, oil is delivered under pressure then released through jets causing the bowl to begin turning. An IOW centrifuge has a central disc stack which the oil then travels through as particles are drawn out through the disc stack to the outer bowl wall.

The IOW bypass centrifuge filter extends the lifespan of machinery by improving ISO codes

The centrifugal force created within the filter will draw out any particles denser than the oil, meaning even submicron contaminants will be removed. As the filtration process occurs, the particles build on the outer wall to form a sludge cake. The purified oil then exits via the top of the centrifuge filter and returns to the sump, ready to lubricate your engine. As the sludge cake thickens, the rotation of the centrifuge filter slows, which will then be illustrated on the remote monitoring unit. The IOW range of centrifuge filters was designed to eradicate basic problems not addressed by previous manufacturers making it completely different to other centrifuge filters available. These design changes were successful resulting in the new filtration technology being 150% more efficient than existing products.

IOW Group centrifuge filters are the only spinner type separator available with remote monitoring options.

Monitoring your centrifuge filtration system

The remote monitoring units (SCUs) are ideal for the trucking industry. Busy truckers who work hard want the peace of mind that their centrifuge filtration system is working without taking the time to service the filter to find it was not required. The IOW SCU0002 device shows the current RPMs (rotation per minute) on the external screen, so the filter's performance can be easily checked.

For those truck drivers who would like the data provided directly to their fingertips, there is the IOW SCU0003 CentriClean SCU. This separator control unit connects via Bluetooth to the CentriClean app (available for Android and Apple devices). You can see live data, gain access to manuals, order spare parts directly from the manufacturer, and add notes regarding the centrifuge to share within a team.

Both models have the feature to set alarms to schedule service, if RPMs drop, or when a set amount of run hours has completed. All these aspects will assist in using fewer resources, fewer man-hours, and less time overall spent on the filtration system as live data is so easily accessible!

Using an IOW Group bypass centrifuge filter will improve your ISO cleanliness codes!

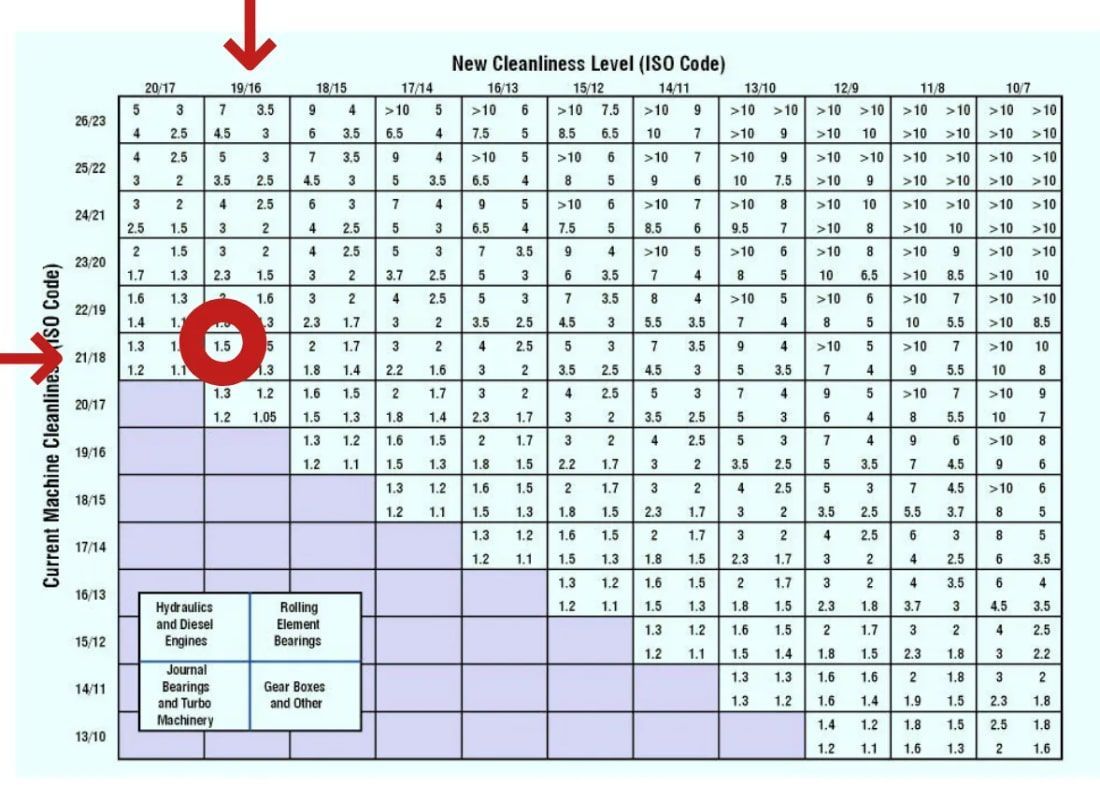

t’s the combined patent-protected technologies incorporated into an IOW centrifuge bypass filter that makes it so much more powerful than any other product currently available. To measure the success of the centrifuge filter, regular oil analysis should be carried out. The ISO cleanliness codes indicate contamination levels within the lube oil and include data such as particle counts. By using these ISO cleanliness codes within an engine life extension calculator, you can see the long-term benefits of installing an IOW centrifuge filter!

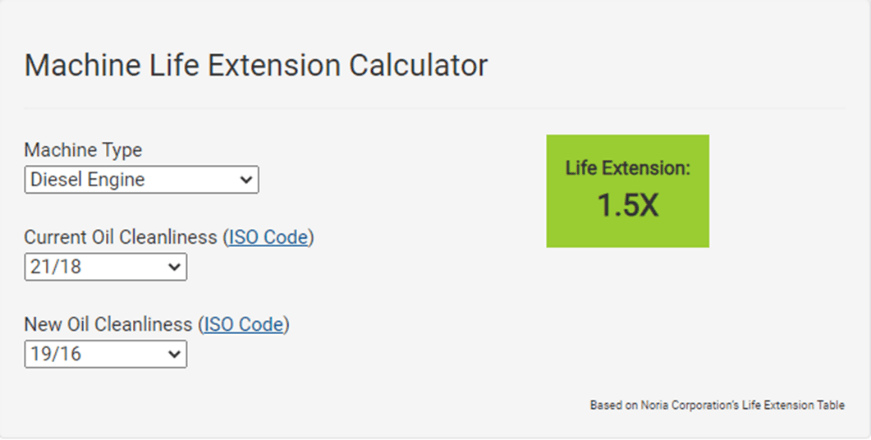

An IOW MP090 centrifuge bypass filter was retrofitted to our customer's truck with a CAT 3406 engine. Initially, the ISO code was logged as 21/18/12, but after installing the IOW MP090 centrifuge bypass filter, the ISO cleanliness code improved to 19/17/12 (as indicated in the table below). This was a significant improvement, and when inputted into the engine life calculate (below), it showed the engine lifespan had been increased x 1.5!

The ISO cleanliness code chart above can help establish the condition of your machinery

The ISO codes reflect the excellent performance of the IOW centrifuge filter and the considerable reduction in harmful contaminants present in the oil. By reducing these abrasive particulates, the engine components will last longer and, as a result, reduce your maintenance budget and the total cost of ownership (TCO). Not only that, by investing in an IOW centrifuge filter, you can avoid unexpected downtime and engine failures. Ensuring your lubrication oil is clean means your engines run smoother for longer... Giving you miles more out of your truck engine.

The Noria machine life extension calculator uses ISO codes to indicate if lube oil is pure enough to extend machinery lifespan

The trucking industry is under increasing pressure to improve efficiency, sustainability and with fewer resources and lower budgets. The simple answer? Invest in an IOW centrifuge bypass filter for your truck engine. Regarding the IOW centrifuge bypass filter, due to the extended oil change intervals and the engine consuming less oil, the IOW centrifuge would be paid back within a year.

A short animation outlining the unique features and benefits of an IOW bypass centrifuge filter

Find out today how a bypass centrifuge could benefit you and your truck engine!

Fill in the contact form below and one of our team will be in touch to find the best filtration and monitoring option for you.