Industry: Marine

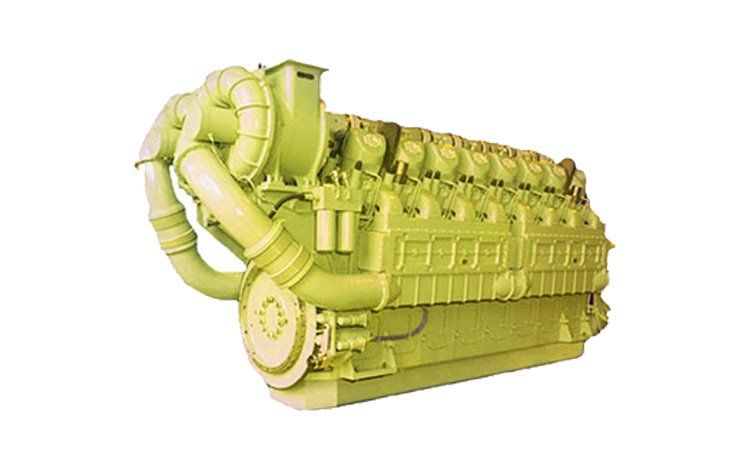

Engine: EMD 16-645

Model Installed: IOW MP600 Centrifuge filter & SCU0002 CentriClean Remote Monitor

The IOW MP600 centrifuge filter and CentriClean SCU0002 monitoring unit were installed onboard this vessel

A Brief History:

The EMD 645 is a two-stroke diesel engine designed and manufactured by the Electro-Motive Division (EMD). The EMD 645 series engines entered production in 1965. They were a logical extension of the 567C achieving a greater power output without changing the external size or weight of the engine, therefore achieving significant improvements in horsepower per unit volume and per unit weight. The EMD 645 has a maximum engine speed of between 900 and 950 revolutions per minute (RPM) and was intended primarily for locomotive, marine, and stationary engine use.

The EMD 645 diesel engine is a two-stroke engine popular in locomotive, stationary and marine situations

The Installation:

Our customer approached us to install an IOW centrifuge filter onboard their vessel along with an SCU (Separator Control Unit) and an IOW Mechline 038 N2 triple screw pump. After hearing about the outstanding performance of the IOW centrifuge and the benefits to the engine and owner, they were keen to see the results for themselves!

In most installations, the IOW centrifuge filters directly take the oil inlet pressure from the engine lube oil circuit. The lubricating oil system on the EMD 2-cycle engine has little excess flow, and the pump does not have enough pressure to operate the centrifuge filter effectively. An IOW Mechline 038 N2 triple-screw pump was installed to create a bypass circulation system. The IOW Mechline 038 N2 pump ensures that the IOW MP600 centrifuge filter has enough flow and centrifugal force to remove the debris and soot the primary filters miss.

After discussing requirements with the customer, it was decided the IOW MP600 centrifuge filter, and CentriClean SCU0002 monitoring unit would be best suited for this environment. For the pump, the model selected was the IOW Mechline 038 N2 pump. Due to the limited space in the engine room, the CentriClean SCU0002 remote monitor was installed in the engine control room for easy access to the live data provided by the SCU monitor.

The IOW MP600 centrifuge filter and triple screw pump installed onboard vessel to clean lubrication oil

The Results

The centrifuge and pump were successfully installed in the engine room. Filtering the lubrication oil to the highest standard for this EMD 16-645 engine. The CentriClean SCU0002 remote monitoring unit was placed in the engine control room for easy access to check the centrifuge filter performance.

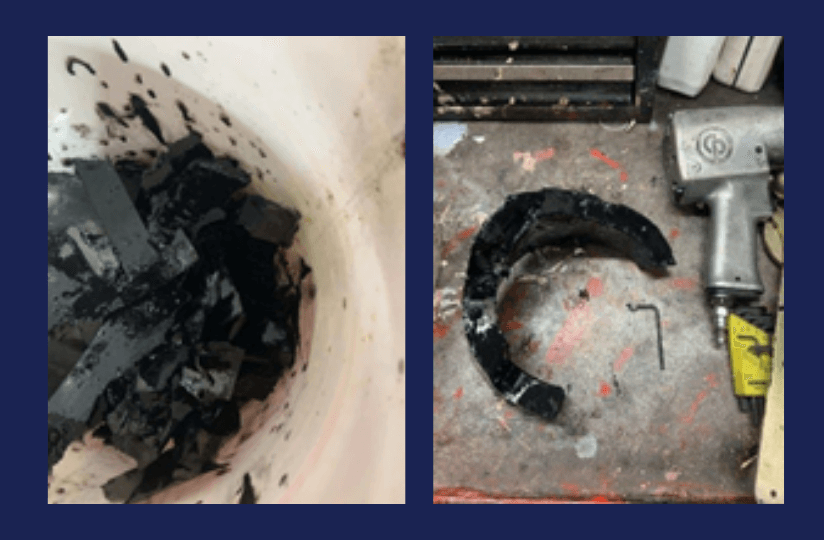

After 1800 run hours, the IOW MP600 centrifuge filter was serviced, and the sludge that was collected inside the outer bowl wall was removed to be safely disposed of. The sludge removed after 1800 run hours was 7.5 lbs (3.4kg). A dirt removal rate of almost 1.9 grams per hour! The centrifugal force created by the centrifuge filter forces the sludge, soot and debris to collect on the outer centrifuge bowl wall.

The CentriClean SCU0002 monitor displayed 4272 RPMs at 86 PSI (5.9 bar). The faster RPM means a greater centrifugal force is created to remove the maximum amount of contaminants from the lube oil.

Sludge collected in the centrifuge filter after 1800 run hours weighed 3.4kg

The Products:

The IOW MP600 Centrifuge Filter

The IOW MP600 centrifuge filter is designed for an oil sump capacity of 190-1550 liters (41.8-341 gallons). The IOW centrifuge filter turns faster than any existing market product. Due to the higher speeds of the IOW centrifuge filter separate solids from the lubrication oil quicker and more effectively than any other centrifuge filter currently on the market. The IOW centrifuge bowl is completely sealed to avoid cross-contamination between the cleaned and dirty oil. The IOW MP600 centrifuge filter has a unique central disc stack, which significantly improves the efficiency of the separation process — drawing out the smallest particles to the outer bowl wall, ready to be collected and disposed of.

The CentriClean SCU0002 Remote Monitoring Unit

The IOW MP600 centrifuge filter and pump installed on vessel

The CentriClean SCU0002 is designed to monitor the performance of the centrifuge. During its regular operation, it will continuously display the current RPMs of the centrifuge and monitor run hours. Alarms can be set to alert the operator when run hours have been completed or if the performance of the IOW centrifuge reduces. Having alarm systems in place saves on precious man-hours, helps utilize fewer resources, and ensures your filtration system is working to the best of its ability.

The CentriClean SCU0002 monitoring unit is Modbus compatible with existing systems. The unit requires 12-24 volts DC to operate and is provided via the power terminal block. The centrifuge filter sensor is a 3-wire device and requires +5 volt supply.

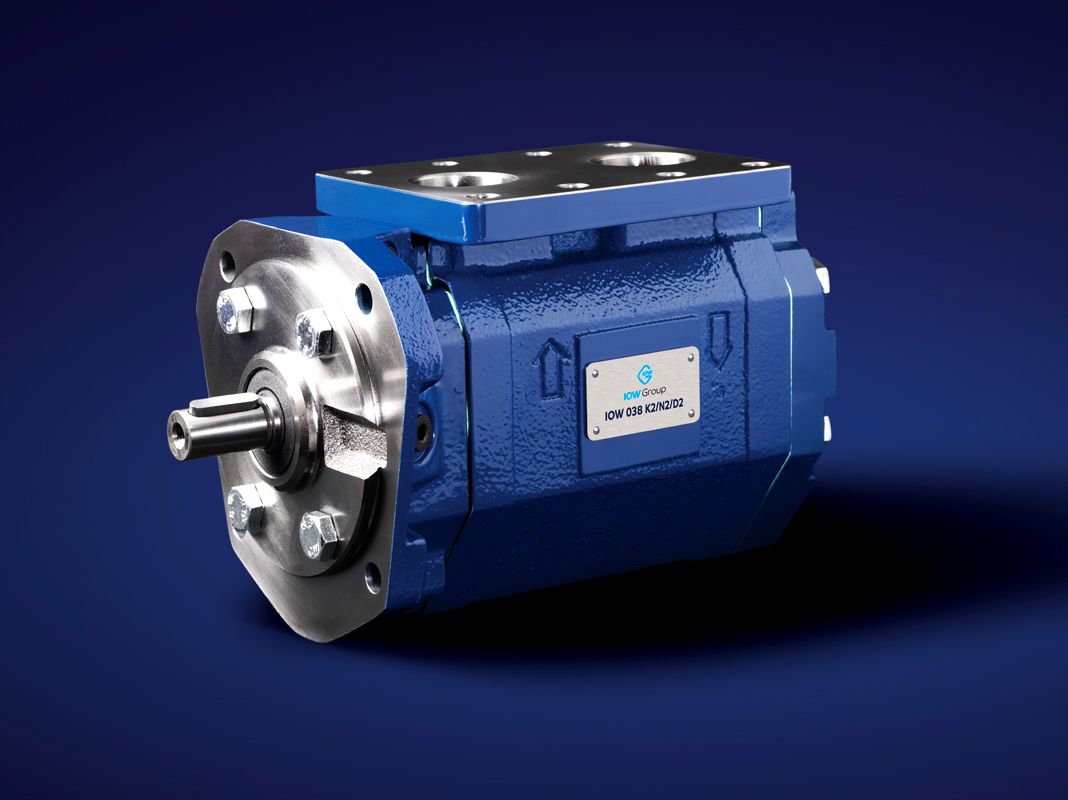

IOW 038 N2 Triple Screw Pump

The sludge monitoring unit (SCU) was installed in the engine control room

The IOW Mechline pumps are mechanically sealed pumps. The mechanically sealed pumps are more economical due to the shaft seal design.

The IOW Mechline 038 series 2 model is ideal for flow volumes of 46-179.8 liters per minute (12.2-47.5 gallons per minute). They have a max differential pressure of 16bar (232 PSI) and can pump fluids at a temperature between -20°C up to 155°C (-4°F up to 311°F). Three different rotor leads are available for the IOW Mechline 038 series 2 pump (K/N/D) depending on the performance required, and the maximum RPM for the IOW Mechline 038 series 2 pump is 3600 RPM.

All IOW pumps are manufactured to the highest standards and designed to fit a range of industry standard footprints for easy installation.

The IOW Mechline 038 series 2 pump is suitable for a flow rate of 46-179.8 liters per minute (12.2-47.5 gallon per min)