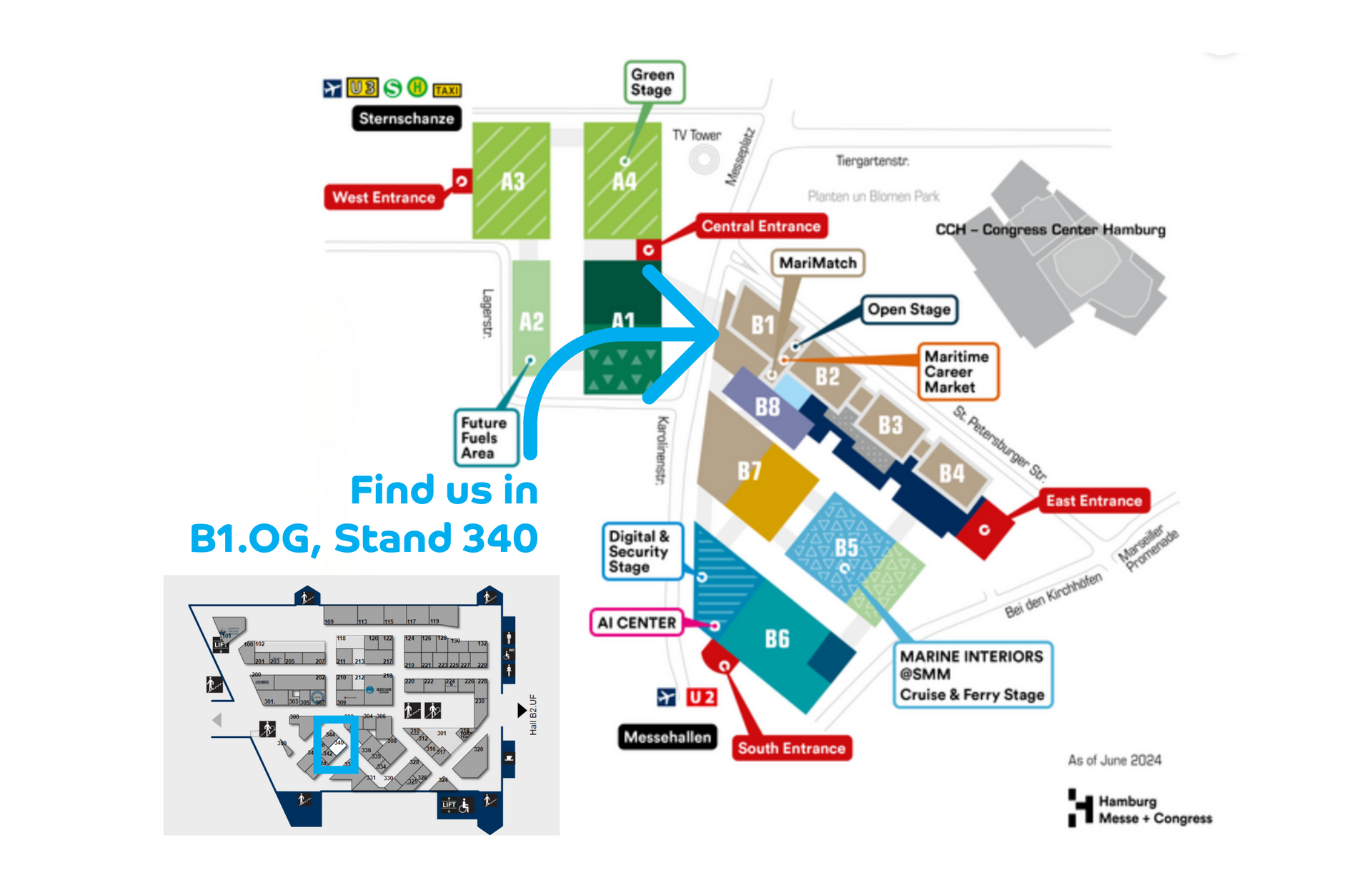

SMM Hamburg 2024 is being held at Hamburg Messe und Congress in Hamburg, Germany from September 3rd 2024 finishing on the September 6th 2024. Find IOW Group at B1.OG.340 where our team of experts are on hand to transform your oil filtration system. To register your interest and book a meeting with our team, please fill out the contact form below.

Find us in B1.OG, Stand 340

IOW Group are exhibiting at Stand B1.OG.340.

Want to know more about SMM Hamburg?

SMM Hamburg is the world's leading trade fair and conference event for the maritime industry that attracts 40,000 participants from over 120 countries. IOW Group are one of 2,000 companies exhibiting, presenting our state of the art technologies and services that are proven to transform oil filtration systems.

Visit IOW Group in B1.OG, Stand 340.

IOW Group Products

Centrifugal Oil Filters

150% more efficient than any other centrifuge of its size with remote monitoring as standard.

eQlyps

A complete filtration solution, equipped with the Q Series Backflushing Filter, MP Centrifuge and Pump.

IOW Group's Pump Range

Positive displacement triple screw pumps that exceed the quality of other manufacturers.

Customer Installations

Check out our successful customer installations on a variety of different engine manufacturers below.

If you are attending SMM Hamburg 2024 and would like to discuss improving your pumping and filtration setup, then please visit our team at B1.OG.340

Alternatively, fill in the contact form at the bottom of the page and we will be in touch.

Contact the IOW Group

We will get back to you as soon as possible

Please try again later